Brick in many different types and shapes, is still one of the most widely used materials in the building.

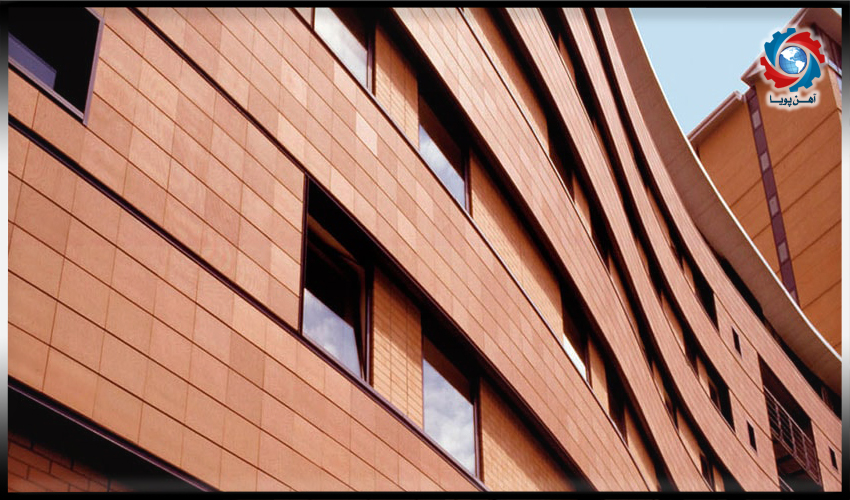

Just as a variety of materials in the construction industry, due to the integration with technology, have made significant progress, the types of bricks have undergone many changes from the past to the present, and in addition to construction, in interior design and The exterior of the building also played a special role.

Brick is different in terms of its types , but in general , bricks as one of the oldest construction materials of man , mud is a flower that is used in different shapes and sizes in construction . In other words, bricks are blocks of regular size and cubes that are often made of clay and are used in different types and designs, at different prices, in different parts of the building. The brick property of the first stages of construction will be subject to the attention of the builders . Brick is used in various construction projects due to its greater use and more reasonable price compared to other building materials.

Bricks have different and varied applications due to their easy transport, small size and ease of use, the most important of which can be mentioned as follows :

1.Flooring due to good abrasion resistance

2.Wall covering and facade for resistance to temperature and humidity

3.Foundation for proper compressive strength

4.Decorative element and decoration of the building

5.Architecture such as wide openings in the form of arches, arches, domes, earrings, Mogharnas

The main structure and substance of brick , clay , usually mix with 15 - 20 % of its weight , mix water and make mud - made mud . Bricks are made from the baking of clay and the changes that occur in it due to heat.

Inside the clay, there are compounds such as limestone, sulfates, oxides and phosphates, and the amount of reduction or increase of each of them should be considered in the clay used to make bricks.

According to existing standards, the amount of these compounds in clay are :

Oxides include silicon oxide 40 to 60%, aluminum oxide 9 to 21%, iron oxide 3 to 12% and magnesium oxide up to 4%

Lime: up to 30% in the form of round limestone

Sulfates of calcium (gypsum), magnesium, potassium and sodium in small amounts; Gypsum about 1%, sodium and potassium chloride up to 1%

Sand: 10 to 15%

Ordinary bricks are used for construction purposes, and are produced by machine or manually. Brick is made, prepared and produced in the following six steps :

1.Soil extraction from the earth surface : transporting it to the plant , tearing up the soil , vegetable soil , and plant roots and … from it .

2.Soil treatment or preparation of raw materials: primary crushing, turning soil into soil, sieving water, sending to the mill and separating grains that lose color or increasing the amount of iron oxide in the soil (if the color of the product is important Be).

3.Making mud to produce clay: Adding water as allowed and stirring in mechanical mixers for adhesion and shaping.

Masonry or molding: including traditional and modern methods :

Traditional method : placing the flower in a wooden mold without a cup, smoothing it by hand, removing the mold and placing the bricks in the open air to dry it.

Methods of brick factories or brick production: including hard mud or extruder method (with 15% water per soil weight), loose mud (for soils with high water content 20 to 30% soil weight) and pressing semi-dry soil or compact mold (with 7 to 10% water by soil weight).

Drying bricks : Sending bricks to the kiln after drying (in the traditional method of picking in the sun from 3 to 15 days) and in today's method, drying in rooms or tunnels that heat from the heat of the kiln (between 38 to 204 degrees Celsius) ) Is supplied with a time between 24 to 48 hours.

Baking clay (bricklaying): The most important stage of brick production. Bake at a temperature of about 900 degrees Celsius for 40 to 150 hours, depending on the type of kiln and clay.

1.Up to 100 ° C: Evaporation of physical clay water

2.Up to 500 ° C: Chemical evaporation of clay water

3.Up to 900 ° C: turning clay into paste, sticking soil grains together and hardening

Also , by adding fuel at the last stage at a certain time , it can be produced in a particular color .

The dimensions of the brick have changed many times from the past to the present. In the past, in addition to ordinary bricks, military bricks with dimensions of 50x50x50 and Khatai bricks with dimensions of 25x25x25 were produced, which were mostly used for flooring, but today, most masonry bricks are made with dimensions of 20x10x5 or 22x11x5.5 cm. In this case, each dimension of the brick is twice as large as the other, so that for masonry, the bricks can be easily arranged in order (length); In such a way that the brick joints do not face each other and the necessary fastening is created between them.

Types of bricks can be classified according to different criteria. Below are some of these divisions :

1.The first division according to the type of construction : traditional and old (pressure / manual), new and modern (machine)

2.The second division according to material: enamel, clay (Italy), refractory, calcareous sand, compressive and machine

3.Based on appearance and shape: solid, hollow, perforated, porous, with different geometric shapes

4.Based on the color in Namachini: white brick (pale yellow), Bahi brick (bold yellow), bright red, garlic red, ablaq (red and yellow)

5.By date (old bricks): military bricks, Khatai bricks, flat bricks (Persian rectangles), sugar bricks

6.Based on aluminum bricks (refractory bricks): aluminum refractory bricks, silica refractory bricks, special refractory bricks, chromium-corundum refractory bricks, zirconium refractory bricks, alkali refractory bricks.

Ahan Pouya with more than a decade of best-selling experience, adheres to professional and ethical principles in the field of selling and buying at inside and outside the borders of Iran, helping you in the steel industry.