Application of steel plate in buildings

Before introducing the application of steel plate, it is better to have a definition of these products first. Technically, sheet metal or sheet metals are sheets about six millimeters thick, which are produced both through hot rolling and cold rolling in the factory. Various operations can be applied on the sheet metal, among which riveting, piercing, cutting, pressing, folding, shaving, etc. Of course, it should also be added that sheet metal is produced in several types and each has its own application in different industries.

Since sheet metal is of high variety, their application is both varied and related to the same type of sheet. To better understand the application of these products, we have listed the type and application of these products separately.

This type is the most common type of sheet metal that their stainless properties are due to the presence of a significant percentage of chromium and also increase the quality of the product. To increase the quality of the sheet, they usually use elements such as molybdenum and nickel along with chromium. Stainless sheet metal is resistant to various environmental conditions such as rain, salt, acid and alkali. Its applications are abundant due to the special properties of the product.

One of the applications of this product is the use in shipbuilding, aircraft manufacturing and automotive due to the elasticity of this sheet metal.

Its other application is in various industries that are used to process liquids and chemicals, such as the oil and petrochemical industry.

For pressurized devices such as press machines and the like, sheet metal is also used because it has a flexible sex sheet and good elasticity.

Stainless sheet metal is also used to insulate and prevent burnout of parts that are constantly in contact with water and liquids.

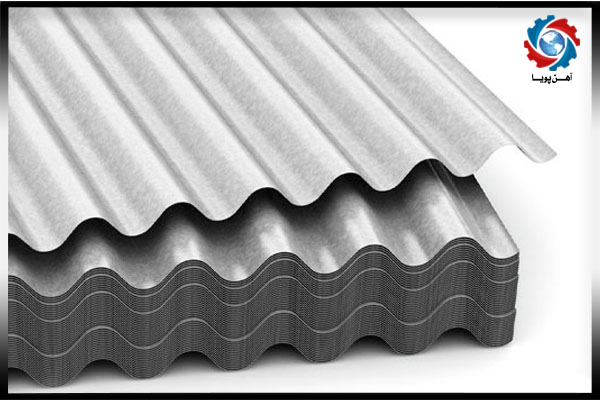

Corrugated metal sheets are widely used in both construction and commercial industries due to their robustness and lack of chemicals. The corrugated sheet itself is made of stainless metal sheet which is produced by cold rolling method, roller and press in wavelets in different designs. The criterion for selecting a corrugated sheet metal sheet is based on its shape and wave pattern. The most important feature of the corrugated metal sheet is its extraordinary elasticity, which is said to be greater than steel.

These products are used to make a variety of containers and conexes because they are very firm and have little impact on them.

It is used to beautify the city and create decorative walls.

In construction use, corrugated sheet metal is used to build roofs, especially in areas where rain, snow and hail fall for most of the year.

Since this sheet is anti-warp, bezel and bending, it is used in various industries where such features of sheet metal are expected such as aircraft manufacturing, arms manufacturing, niches, etc.

Copper is a metal with extraordinary properties. This metal is also a good conductor for electricity, temperature and metal, and is stainless and corrosion. Therefore, wherever there is a need for such properties, copper sheets are used. This sheet is mostly used to make mobile electronic components, etc. because it is not worn out and is a good conductor for electricity and heat. One of the special and extensive applications of this sheet metal is the use in the manufacture of various electrical wires and cables. The wires that are made with this sheet of metal have considerable strength and long life while providing better performance than other wires.

Another application of copper sheet is that they use it to make a variety of kitchen utensils. Cooking with dishes made from copper sheets attracts zinc element into food that is very useful for the body. This sheet is used to make a variety of jewelry and decorations that have countless fans. They also use it to make metal furniture.

In terms of application, another steel sheet is its galvanized type, which is used in countless industries and structures. This product is also a stainless sheet metal, but has a different coating than the normal stainless sheet. Galvanizing metal sheets is done in two ways. The electro-galvanized method in which the sheet is placed in an electrolyte solution and a thick layer of zinc metal is formed on it. This coating is well absorbed to the surface of the sheet in this way, making it multiplier protection against corrosion, burnout and rust.

The high-temperature cladding method is another method of galvanizing the sheet metal. In this method, it is applied to the sheet through the heat treatment process. Zinc is absorbed by this method, but its thickness is less. In the electro-galvanized method, a impurity layer is formed along with zinc on the surface of the sheet, but in the high temperature method there is no impurity layer. This sheet has a high price due to its unique properties and high strength and is also used for a wide range of industries.

Galvanized sheet metal is widely used in architectural purposes such as hedge construction, staircase, ladder, shield, fence, canopy, conduit, office and metal furniture.

It is one of its other applications in the electronics industry and it is used to manufacture electronic components, instrumentation, etc.

Its application in the industry is also widespread and it is used to make a variety of industrial bolts.

In order to plumb and to prevent the pipes from being eaten, they are placed in the columns made with this sheet of metal.

They also use galvanized sheet metal to make various pipes, whether industrial or construction.

One of the most important applications of this sheet is the use in isolation or insulation sections.

Another application of this sheet metal is the use in the manufacture of cabinets, water transfer pipes, liquid storage tanks, etc.

Brass metal is a type of copper alloy that is made using zinc element. Based on the amount of zinc combined with copper, five types of brass sheet metal are produced. Brass sheet cartridge, red brass sheet, well-carved brass sheet, sea brass sheet, 330 brass sheet. One of the main reasons why brass sheet is widely used is its extraordinary resistance to erosion, so that the piece made of brass sheet has its quality and healthyness for many years. Another reason for the high use of this sheet metal is its lightness. The well-produced brass sheet has high strength and elasticity, is erosion resistant and has a light weight.

One of the applications of this sheet is ceiling design, interior and exterior decoration design.

Due to the suitable cutting properties, it is used to make machines and machines in which parts of different shapes and sizes are required.

Brass sheet metal is also used in industries where light yet robust tools should be used.

Ahan Pouya with more than a decade of best-selling experience, adheres to professional and ethical principles in the field of selling and buying at inside and outside the borders of Iran, helping you in the steel industry.