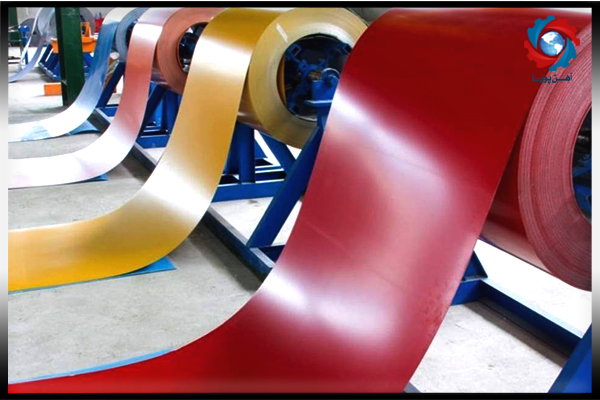

In today’s world, the use of durable, aesthetically pleasing, and cost-effective raw materials in various industries has become essential. One of the widely used materials that has gained significant attention in recent years is the colored steel sheet. These sheets, produced with different color coatings, not only offer an attractive appearance but also provide high resistance to corrosion, moisture, and environmental factors. In this article, we will provide a comprehensive overview of the types of colored sheets, their features, production process, and applications in various industries.

A colored sheet is a type of galvanized or Aluzinc sheet that is coated with one or more layers of electrostatic paint and then cured in special ovens. This process creates a durable and uniform layer of color that enhances the mechanical and chemical resistance of the sheet.

Colored sheets come in various types, often categorized based on the base metal used, the coating material, or the final application. The most common types include:

1. Galvanized Colored Sheet

2. Aluzinc Colored Sheet

3. Pre-Painted Sheets

Each type offers specific features in terms of durability, flexibility, and resistance to environmental conditions.

Colored sheets have numerous advantages that have led to their widespread use in industry, including:

1.High resistance to corrosion and rust

2.Aesthetic variety with different colors and finishes

3. Long lifespan and low maintenance

4. Flexibility and ease of installation

5.UV and moisture resistance

6.Lightweight compared to traditional materials

The production of colored sheets begins with galvanized or Aluzinc coils that are cleaned and degreased. They are then coated with electrostatic paint in multiple layers (primer, base coat, topcoat) and cured at high temperatures. This multilayered coating not only enhances the appearance but also increases the sheet’s resistance to physical and chemical damage.

Colored sheets are widely used in a variety of industries due to their unique properties, such as:

1.Construction and Architecture: Used in roofing, façades, false ceilings, and decorative panels

2.Household Appliances: Employed in the body of refrigerators, washing machines, and other devices

3.Transportation: Applied in vehicle parts and containers

4.Advertising and Signage: Used for billboards, signboards, and promotional panels

5.Furniture Industry: For decorative surfaces and structural components

These sheets are available in different thicknesses, usually ranging from 0.18 mm to 1.2 mm. Their width often varies between 1000 mm and 1250 mm, and the length is cut according to customer requirements. The ability to customize sizes makes them suitable for a wide range of applications.

Colored sheets are produced in a variety of colors to suit different tastes and applications. The most commonly used colors include:

1.White

2.Red

3.Blue

4.Green

5.Orange

6.Yellow

7.Cream

8.Silver

Manufacturers of colored sheets adhere to international quality standards such as ISO, ASTM, and EN. These standards ensure the durability, paint adhesion, corrosion resistance, and color stability of the sheets. Regular testing and quality inspections are carried out during the production process.

Colored steel sheets, thanks to their aesthetic appeal, high resistance, and diverse applications, have become an indispensable component in many industries. Choosing the right type of sheet with appropriate coating and dimensions can significantly increase the efficiency, longevity, and beauty of industrial and construction projects

Ahan Pouya with more than a decade of best-selling experience, adheres to professional and ethical principles in the field of selling and buying at inside and outside the borders of Iran, helping you in the steel industry.