In modern construction, the use of materials that are both lightweight and strong has gained significant importance. One such essential material is the Knauf profile, a key component in the substructure of Knauf systems that has found a special place in contemporary dry construction and interior architecture. In this article by Ahan Pouya, we present a complete overview of Knauf profiles, their applications, benefits, types, and manufacturing process.

A profile refers to solid or hollow metal sections with a consistent cross-section and considerable length. These sections are typically made from steel, aluminum, or galvanized steel, and play a critical role in civil, structural, and industrial construction. Common uses include doors and windows, metal columns, railings, and substructures for Knauf systems.

Knauf refers to coated gypsum boards categorized under lightweight and dry construction materials. These boards are used in false ceilings, partition walls, interior decor, and insulation systems. Due to their lightweight nature, ease of installation, and repairability, Knauf dry construction systems have rapidly replaced traditional materials like plaster and brick.

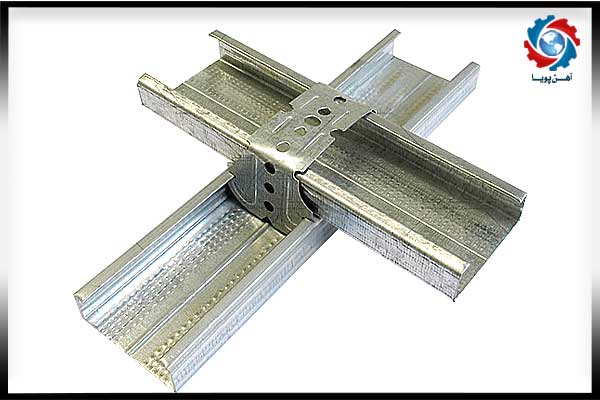

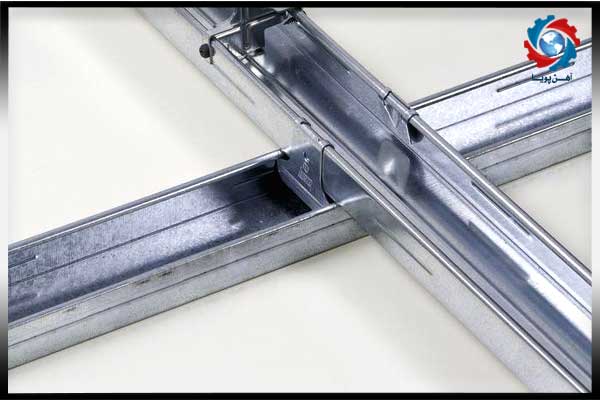

Knauf profiles are metal sections, primarily made of galvanized steel, that serve as the main framework alongside gypsum or cement boards in Knauf systems. These profiles form the structural basis for false ceilings and walls and enable various interior design implementations.

:Thanks to their structural and technical properties, Knauf profiles are used in a variety of projects, including

Modern interior design

Multi-layer or simple false ceilings

Renovation of old buildings using modern techniques

Interior partition walls

Enhancing thermal and acoustic insulation

Covering installations in ceilings and walls

Building decorative shelving

:Knauf profiles offer many benefits that have made them increasingly popular among engineers and designers

Lightweight: Easy to transport and install

Earthquake resistant: High flexibility and low weight help absorb vibrations

Fire resistance: Materials used are heat-resistant

Fast installation: Quicker than traditional construction methods

Cost-effective: Lower total cost compared to masonry

Design flexibility: Suitable for unique architectural designs such as curves and artistic features

Crack resistance: Flexible nature prevents cracking unlike cement walls

Thermal and acoustic insulation: Enhances energy efficiency and occupant comfort

Compatible with various climates: From humid to arid regions

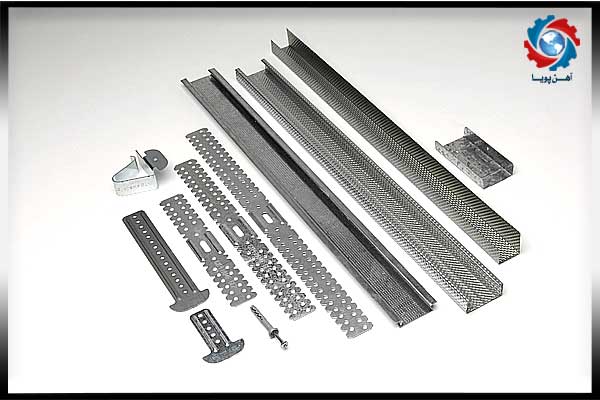

:Knauf profiles are categorized into two main groups based on their use

Galvanized Ceiling Profiles

Galvanized Wall Profiles

:Each category contains various types

C-shaped Profiles: Primarily used for partition walls. Installed vertically between U-profiles at intervals of 30, 40, or 60 cm. Allow cable passage.

U-profiles (Runner): Horizontal components used on floors and ceilings to guide C-profiles. Produced in 50, 70, and 100 mm sizes

. L-profiles (Leveling): Installed at ceiling-wall joints for leveling purposes, using tools like laser levels

. F-profiles: Main support profiles in false ceilings, also used in protective walls

U36 Profiles: Support F47 profiles in ceiling or protective wall structures. Connected with Knauf-specific screws

: Support Structures

.SP60: For pipes and building installations

.SC47: For electric wiring systems

Galvanized steel sheets (0.3 to 0.6 mm thick) are cold-rolled, shaped using roll-forming machines, and molded into required shapes without heat, preserving the base metal's mechanical properties.

Installation requires specialized tools, including

Support jacks and lifts

Roller or longitudinal cutting machines

Special knives for cutting Knauf boards

Automatic screwdrivers

Punch pliers

Sheet cutters

Angle trowels and special screwdrivers

Trowels, sandpaper, and leveling cords

Various brands manufacture Knauf profiles in Iran. The quality and compliance with standards affect performance and lifespan:

Knauf Iran: A pioneer using German technology, manufacturing DIN-compliant profiles

Gach Barge: A trusted brand for gypsum boards and related profiles

Alborz Panel: Offers competitively priced metal frames for residential and office projects

Top Panel: Specializes in ceiling profiles with various thicknesses suited for Iran’s climate

Imported Brands (e.g., Knauf Germany): Used in luxury or specialized projects

To ensure quality and safety, both national and international standards must be followed

DIN (Germany): Covers mechanical, chemical, and dimensional specs

ASTM (USA - C645, C754): For light galvanized metal profiles in ceilings and walls

ISIRI 1-12015 (Iran): National standard for dry construction systems

EN 14195 (EU): Common in imported profiles

Sheet thickness: Less than 0.5 mm may lack strength

Galvanization quality: Higher zinc coating equals better corrosion resistance

Standard compliance: Ask for technical documentation

Project type: Domestic brands suit homes; international ones are better for large commercial projects

nauf profiles are transforming dry construction with their lightweight, fast installation, cost-efficiency, and versatile usage. If you're looking for modern, durable, and flexible building materials, Knauf profiles are a perfect choice

Ahan Pouya with more than a decade of best-selling experience, adheres to professional and ethical principles in the field of selling and buying at inside and outside the borders of Iran, helping you in the steel industry.