In today’s fast-paced world of technology and scientific innovation, some materials play a transformative and foundational role. One such exceptional material is Graphene—a substance thinner than paper yet a hundred times stronger than steel! Since its discovery in 2004, graphene has been recognized as one of the most astonishing materials and has rapidly captured the attention of various industries, including electronics, aerospace, medicine, energy, and even steel production.

In this article from Pooya saderaat, we provide a comprehensive overview of graphene—its chemical composition, mechanical and electrical properties, production methods, industrial applications, and the challenges facing its commercialization.

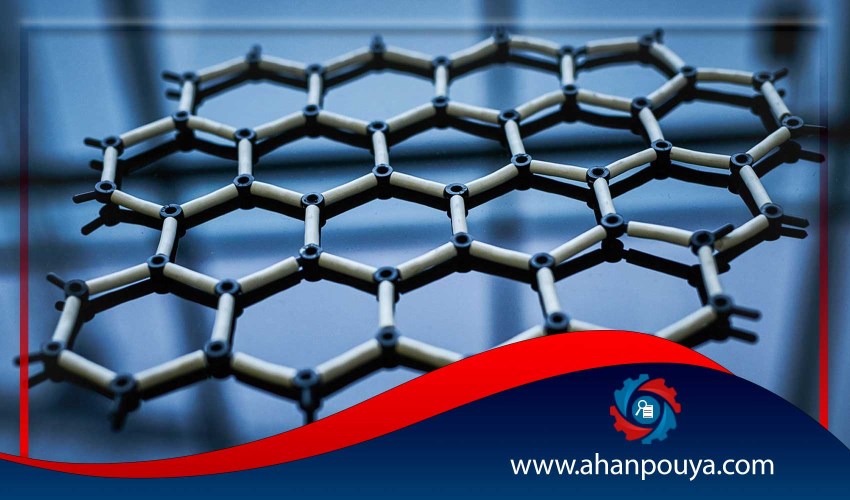

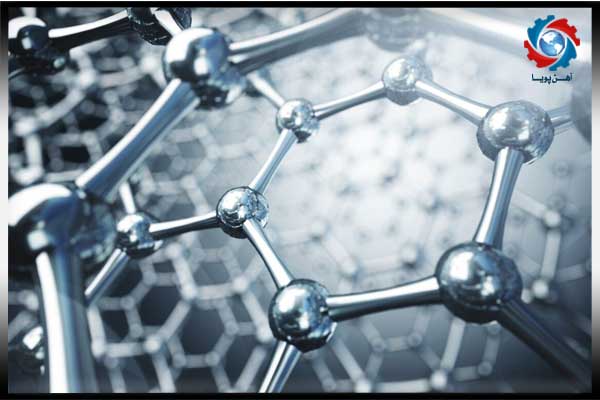

Graphene is a two-dimensional, crystalline material composed of a single layer of carbon atoms arranged in a hexagonal (honeycomb) lattice. This structure gives graphene its remarkable properties such as exceptional strength, high electrical conductivity, and extraordinary flexibility.

Graphene is derived from graphite—the same material found in pencil lead. The difference lies in the structure: graphite consists of multiple stacked layers of graphene.

Graphene has a hexagonal crystal structure where each carbon atom forms covalent bonds with three neighboring atoms. This flat, two-dimensional configuration results in properties like:

1.Thickness on the atomic scale

2.Low density

3.High flexibility

4.Exceptional strength-to-weight ratio

Remarkably, even at an atomic thickness, graphene can transmit up to 97% of visible light while maintaining excellent electrical and thermal conductivity.

High Mechanical Strength: Graphene is one of the strongest known materials, with tensile strength over 130 times that of steel.

Exceptional Electrical Conductivity: Graphene can transport electrons at near-light speeds, making it one of the best electrical conductors ever discovered.

High Thermal Conductivity: With a thermal conductivity exceeding 5000 W/m·K, graphene outperforms copper significantly.

High Flexibility and Elasticity: Despite its hardness, graphene is extremely flexible and stretchable—up to 20% of its length.

Ultra-Lightweight: Due to its atomic thickness, graphene is incredibly light and can even float on a soap bubble.

High Transparency: It transmits up to 97% of visible light, making it ideal for use in display screens and solar panels.

A simple, lab-scale method using adhesive tape to peel layers from graphite. Though key to the discovery of graphene, it is not scalable.

In this industrial method, carbon atoms from gases (e.g., methane) are deposited on metal substrates (usually copper or nickel) at high temperatures to produce uniform, high-quality graphene.

Graphite is first oxidized to graphene oxide, then reduced chemically or thermally to obtain graphene. It's a cost-effective method but generally yields lower-quality material.

In this technique, graphite is dispersed in suitable solvents and exfoliated into single or few-layer graphene using ultrasonic waves.

In the steel industry, graphene can be added to metal composites to improve wear resistance, tensile strength, and thermal conductivity. Particularly in tool steels, it enhances component strength and lifespan.

Due to its exceptional electrical conductivity, graphene is ideal for ultra-fast transistors, logic circuits, and potentially replacing silicon in future technologies.

Graphene is used in advanced lithium-ion batteries, supercapacitors, and fuel cells, leading to increased capacity, faster charging times, and longer battery life.

With its biocompatibility, graphene is suitable for bio-implants, biosensors, targeted drug delivery, and tissue engineering.

As an ultra-thin and corrosion-resistant coating, graphene protects metals—especially in industrial and marine environments.

Its high strength and low weight make graphene ideal for lightweight, durable, and conductive components in modern aircraft and automobiles.

Despite its outstanding properties, widespread use of graphene faces several challenges:

1.High production costs

2.Inconsistent quality in large-scale production

3.Integration difficulties with other materials

4.Need for further environmental and human safety studies

The future of graphene in the steel sector is promising. Researchers are exploring steel–graphene nanocomposites to develop lighter, stronger parts. This innovation could usher in a new generation of high-performance steels. Graphene may also be used to create conductive, anti-corrosive coatings for rebar and steel sheets.

With its simple structure yet complex and unique characteristics, graphene has emerged as one of the most revolutionary materials of the 21st century. It has the potential to transform diverse industries—from steel and electronics to medicine and energy. Given the accelerating pace of research, graphene is expected to make a stronger presence in industrial markets in the coming years. Companies that move early to harness graphene’s potential will undoubtedly gain a significant competitive advantage in the global market.

Ahan Pouya with more than a decade of best-selling experience, adheres to professional and ethical principles in the field of selling and buying at inside and outside the borders of Iran, helping you in the steel industry.