Stainless steel has many unique properties that can be used on a large scale in the construction industry. Significant advances in the material fabrication process have led to the development of double-layer stainless steel, which has excellent mechanical properties: There have also been good advances in cladding for architectural applications. The Structural Research Program provides the basis for national and international advances in specifications, codes, and standards across both the design and construction and installation processes.

Stainless steel has many desirable characteristics that can be used in building applications . The resistance to corrosion and long life enables the construction of thinner and more durable structures . Provides architects with many possibilities such as shape, color and form while being hard, clean, compatible and renewable . The consumption of stainless steel has increased over the last 20 years with a sharp growth rate of 5% and has surpassed the growth rate of other raw materials. The growth rate of the anti - bell steel in the construction industry has been even more . Not just because of the rapid progress in China. It is estimated that about 4 million tonnes of stainless steel were consumed in the construction industry worldwide in 2006, which is 14% of the total amount of steel consumed per year. There is a big difference between the share of countries in the use of steel in the construction industry.

In China, more than 20 percent of stainless steel accounts for this sector, while in Germany it is less than 7 percent. Stainless steel has been traditionally used in exterior and roofing since the 1920s.

There are even examples of the use of steel structurally in later years, for example in 1925 a reinforcing chain was installed on the dome of Powell Church in London to maintain its balance. Today, stainless steel is used in a wider range of structures and architectural components, from small but complex glazed castings to bearings and bridge arches.

Prior to 1980, stainless steel construction applications were more common in minor parts such as porches, interface walls, floorboards and angles, and for prestigious metal cladding. While in the last 20 years, the range of its uses has expanded.

There are many examples of the transfer of advanced technologies for the applications of industrial structures (such as water treatment, breakwater, equipment reinforcement, platforms or stairs, and aerospace industries) to other industries. For example, reinforced stainless steel rods used in the aerospace industry were transferred to the production of yachts, which were later used to build the Louvre pyramid glass wall. This led to subsequent projects, which included very large glass curtains, the use of stainless steel tension rods, cables and hollow profiles to reinforce glass facades with minimal visual impact. Glass and steel fittings are usually cast in two or four points designed to attach glass to a reinforcing structure. The growth of the use of stainless steel in invisible parts of the building has also been very significant Such as plumbing and cooling systems, especially in the Scandinavian countries, Germany and Italy. Efficient connection methods, such as press connections, help limit installation costs. Reducing the maintenance costs of using stainless steel over its life cycle makes it a competitor to materials such as copper or even plastic pipes.

Stainless steels are iron-based alloys with a minimum of 10.5% cream. Suitable corrosion resistance of these steels is due to the formation of a layer of cream oxide on their surface and includes different groups with different properties.

The types of which are as follows :

Ferritic stainless steels

Martensitic stainless steels

Austenitic stainless steels

Two-phase stainless steels (austenite + ferrite)

Stainless steels hard sediment

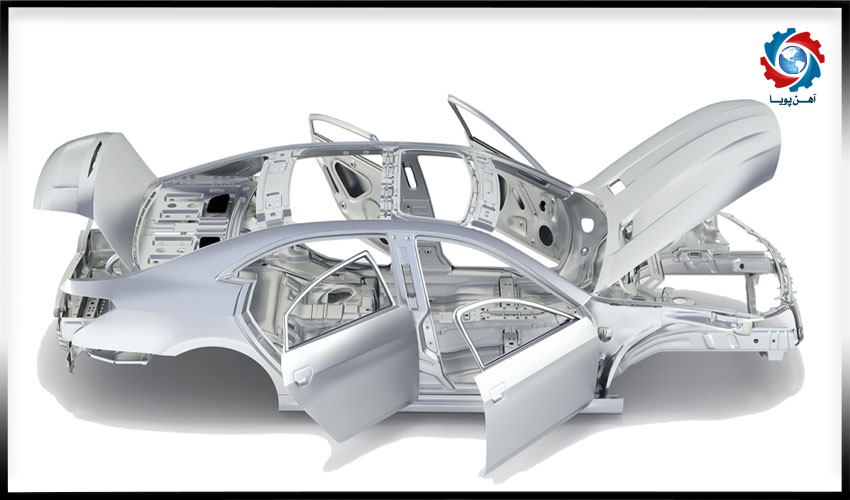

Ferritic stainless steels have a structure similar to pure iron at ambient temperature and have moderate flexibility and corrosion properties and are used in the automotive industry.

Martensitic stainless steels have relatively high carbon, high strength and hardness with moderate corrosion properties and are used in surgical instruments and knife blades.

Austenitic stainless steels have very high corrosion and toughness properties and are the most widely used category of stainless steels and are used in chemical and automotive industries.

Two-phase stainless steels have properties between ferrite and austenitic groups and have high strength and are mostly used in petrochemical industries.

Hardened sediment stainless steels have high strength with moderate corrosion properties and are divided into three categories based on their structure: austenitic, semi-austenitic and martensitic. These steels are used in aerospace and advanced industries due to their high strength.

Ahan Pouya with more than a decade of best-selling experience, adheres to professional and ethical principles in the field of selling and buying at inside and outside the borders of Iran, helping you in the steel industry.