Warsaw alloy is a copper-based alloy with about 65% copper , 18% nickel and 17% zinc used in its construction. In some cases, small amounts of lead, tin and manganese are added to the Warsaw alloy by 1-2% to show better properties when working with it .

Although warsaw alloy is also known in various sources as silver nickel, no silver has been used in its composition and this name is only due to the silver lustre obtained from the Warsaw alloy .

The Warsaw alloy was first made 2,000 years ago by the Chinese from melting copper-nickel ore, which is referred to as Paktung, meaning white copper .

Warsaw alloy has many of the same properties as brass and bronze, which changes the amount of nickel in that warsaw alloy color .

In this way, the higher the nickel content, the closer the color to the silver white, and with less nickel content, the color is close to yellow and shows a color similar to the brass alloy .

In other words , the existence of more nickel content makes the Warsaw alloy more like silver , and higher amounts of copper will make the Warsaw alloy more and more resistant to corrosion .

On the other hand , the existence of greater amounts on the hardness and strength of the Warsaw alloy can be improved and its melting point decreases , but the ductility reduces the Warsaw alloy .

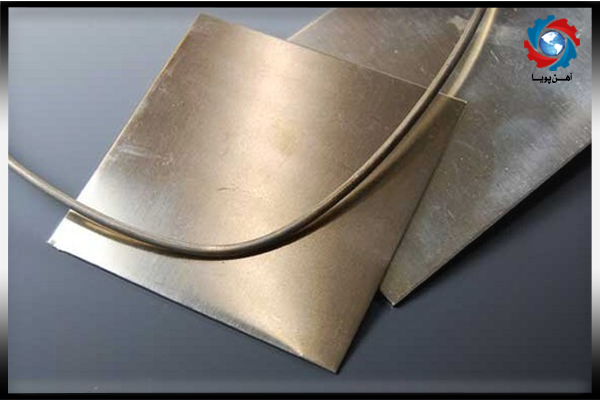

Warsaw alloy is manufactured under casting, rolling, stretching, extruding and machining processes and in case of oxygen exposure, a protective oxide layer is created on the alloy .

Warsaw alloy is a type of hard metal that despite being non-metallic but very hard and resistant to wear .

In addition, it has good thermal and electrical conductivity and is highly resistant to corrosion of the environment. It also has good ductility and depending on the amount of lead in it is suitable for soldering and welding .

Warsaw alloy has been used for various applications throughout history since its inception . In this section, we have divided the applications of Warsaw alloy into two parts : old applications and new applications.

The main application of Warsaw alloy in ancient times is as follows :

Throughout history, it has been customary for different governments to use certain metals and alloys to coin their state emblem. Therefore, warsaw alloy has been used in the manufacture of coins in some countries .

Warsaw alloy has been used for the manufacture and plating of personal jewelry and clothing due to its special and similar lustre of silver .

Plating became warsaw alloy's most basic application in the early 1900s and nickel was identified as an alternative to copper in silver plating. Nickel was harder, stronger and more durable than copper, likewise some use cases include keys, cigarette boxes, car radiators and hub doors .

Due to the fact that warsaw alloy is made of copper, nickel and zinc and the bulk of it consists of copper, it is used in food and beverage transportation equipment .

Because firstly, copper has antimicrobial capability and secondly, the combination of three metals of copper, nickel and zinc in warsaw alloy causes its high resistance to corrosion, which is very important when exposed to the acidity of foods and beverage mixtures .

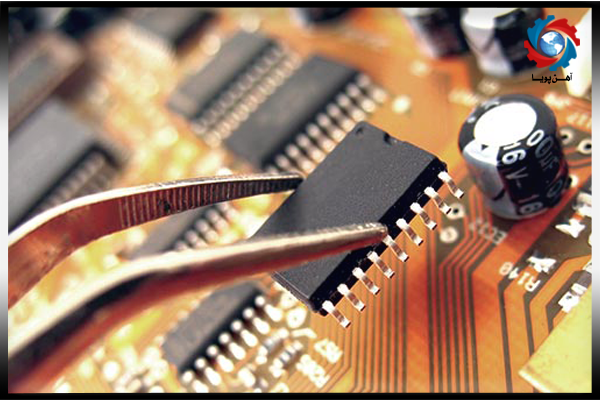

The Warsaw alloy has significant engineered properties that make it a viable option for electrically sensitive applications. Here are some of the applications of Warsaw alloy in the electrical industry :

1.Battery protector

2. Aerospace Programs

3.Connectors & Sensors

4.rigorous laboratory instruments

5. Switch Components

Decorative and functional parts at home such as drawer handles are usually made of Warsaw alloy . It can also be molded into general forms and prefabricated forms to be used independently of the landlord's tastes and tailored to a wide range of styles and decorations .

Warsaw alloy casting shapes under the title of wrought are widely used in buildings today .

Although the color of Warsaw alloy today is mainly silver white, shades of pale yellow, green, pink and blue can also be produced by changing the amount of nickel and can be used in construction .

1.Warsaw alloy has a higher zinc percentage than similar alloys such as brass and bronze, making it look more shiny and beautiful than them. Warsaw alloy, due to its silver-like appearance, can be a cheaper alternative than silver in the manufacture of jewelry and of course has good resistance to corrosion of environmental conditions. For this reason, the stains from welding and manufacturing stages do not remain on it .

2.Warsaw Alloy is located in the high-end alloys group and has good mechanical properties. This alloy, while high in thermal and electrical conductivity and highly resistant to corrosion, is often suitable for sensitive space, medical and laboratory applications due to its ideal electronic properties .

3.Warsaw alloy has better hammering and machining capability than similar alloys and is easily transformed into complex shapes by hot stamping. For this reason, it is more popular than other alloys to work in industry and art .

4.The electrical resistivity of the Warsaw alloy will cause the alloy to be ideal for heating coils , while its corrosion resistance is suitable for sea connections and plumbing means .

5.The Warsaw alloy is non - magnetic and temperature changes have no effect on its resistance .

As stated in previous sections, warsaw alloy has good hammering properties. This property makes it easy to be influenced by intentional and unintentional scratches and lose its appearance in places of building and city where this alloy has been used to make tools and decorations and architectural elements .

Warsaw alloy does not have much tensile strength and therefore cracks under tensile stress conditions .

Due to the high amount of copper, it is sensitive to chromium and nitric acids, and on the other hand, the amount of zinc in warsaw alloy causes the sensitivity of this alloy to acidic and sulfur pollutants and will also be stained in their presence .

Ahan Pouya with more than a decade of best-selling experience, adheres to professional and ethical principles in the field of selling and buying at inside and outside the borders of Iran, helping you in the steel industry.