Cast iron is one of the most important and useful types of iron alloys Which gives the necessary chemical composition with carbon and is in this state. It should be noted that more than 95% of cast iron is iron And that 's why the resistance of this alloy is very high and incredible . Of course, keep in mind that depending on the amount of carbon used in this alloy, you can see many different types of cast iron in the industry, each with its own unique properties and characteristics and they can play a role in different sectors of industry . This alloy is used in many industries today And many chemists are looking to produce one of the best and most durable types of alloys to increase the efficiency of this alloy.

You can see many different types of cast iron The most important of which are the following :

Due to having a very special infrastructure, its cross section was gray . It is one of the most widely used types of iron alloys that has been used in many industries. The most important types are cast iron sheets, spherical, cow eyes and yoghurt cast iron.

With good abrasion resistance, good casting, low melting point, excellent machining and good ductility, this group has been able to play a role in many industries and is one of the most popular types of cast iron.

This case has much less carbon . And because of their white cross section, they have been named with this name . White cast iron is too brittle and this has led to the ban on the use of this product in many industries. A better example of this model of cast iron is the turbine impeller.

Its most important features include being malleable, having mechanical properties, snow shape and having irregular shapes. Note that by heating white cast iron under certain conditions, malleable cast iron can be prepared.

Cast iron contains 3.5% -2% carbon and a small amount of manganese . Impurities in crude iron such as sulfur and phosphorus, the properties of which are adversely affected, are reduced to an acceptable level in cast iron. The melting point of cast iron is between 1470-1420 k, which is less than both of its main compounds, making it the first molten product after simultaneous heating of carbon and iron.

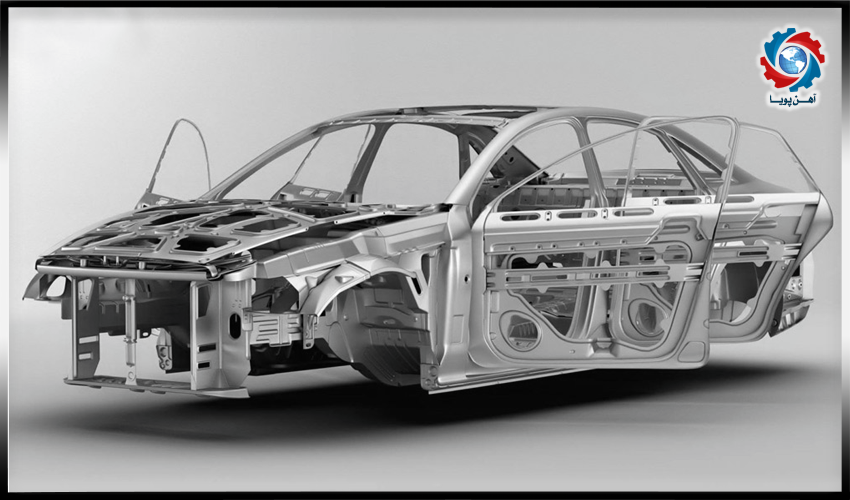

The cast iron is very strong , hard and fragile . Except for the ductile type, this metal is brittle and due to its low melting point, fluidity, castability, machining, non-deformability and abrasion resistance, it has become an engineering material with a wide range of applications and in the production of pipes, machines, parts. Automotive industry such as cylinder heads, cylinder blocks and gearboxes are used.

One of the most important factors that has caused the use of cast iron to increase so much and attract the attention of many industries, is its unique properties. The most important features of this alloy can be referred to as :

1.It turns from solid to liquid without having a doughy state

2.It is malleable

3.It is hard and fragile

4.It rings late

5.It is heat resistant

6.It has a very high resistance

7.There are many types

8.The price is right

9.Heavy weight

The unique features of this alloy have made it one of the most popular and most widely used types of alloys and can play a very important role in many industries. Today, many companies are looking to produce construction equipment from this alloy so that they can design and build much more durable and cost-effective buildings.

It was used to build bridges, pipes, street well covers, machinery, and much more until steel was replaced. Its extended form has been used as roof trusses, rafters, gas lines as well as decorative windows. This cast iron is used in the manufacture of cooking utensils such as saucepan pots.

Cast iron has advantages and disadvantages in architecture . It is strong in compression and weak in traction and bending . Some of the special properties of cast iron that distinguish them from steel are low melting point, high fluidity, low shrinkage during freezing and cooling, low impact resistance, low flexibility, good vibration absorption , Good abrasion resistance and insensitivity to surface grooves . Of course, the strength and hardness of this type of cast iron is very low, especially at high temperatures (when burning). The remarkable thing about the above properties is that many of them depend on the microscopic structure of the field and how the carbon is distributed in it.

Ahan Pouya with more than a decade of best-selling experience, adheres to professional and ethical principles in the field of selling and buying at inside and outside the borders of Iran, helping you in the steel industry.