Have you ever noticed the importance of hot rolled sheets in industry? Because of its strength and unique properties , iron , is one of the most vital metals and even materials in the world . Iron combining with other metals creates different products for different industries such as car parts and construction .

So it is important to investigate existence , applications , properties , and effective factors to determine the price for activists of related industries .

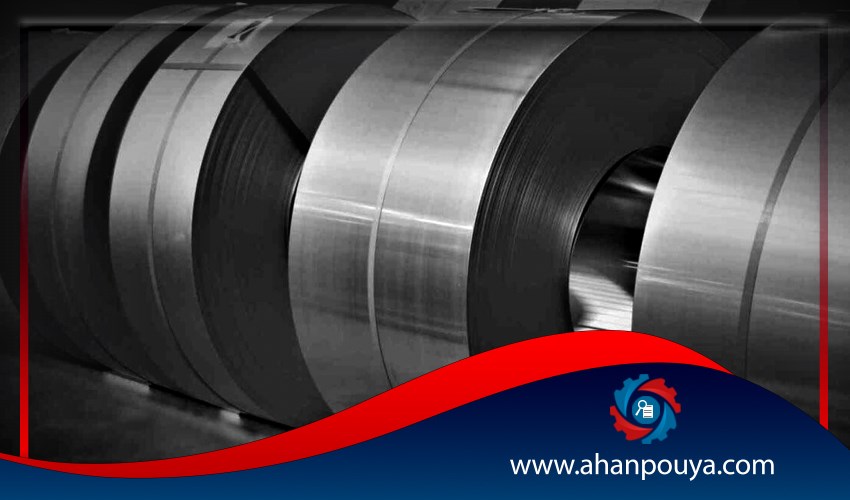

Ironware is divided into two major groups of industrial or structural . The two main groups are then divided into smaller categories . Sheets are marketed as rolls or sheets . These sheets can be referred to as ordinary hot rolled sheet or industrial hot rolled sheet ; which have different technologies to make .

The standards used for making ordinary hot rolled sheet are ST37 ; which are which are more applicable to buildings and niche .

Industrial sheets are used in industries such as petrochemicals , dams and etc. Different types of sheets are producing via hot - rolling and cold -rolling methods . Hot rolling produces hot rolled sheet and cold rolling produces cold rolled sheet .

Hot galvanized sheets are a kind of low carbon steel which are known as 36A and 1011A . High welding point is of characteristics of 36A and in contrast 1011A has high strength and is so suitable to make vessels .

Soft hot tolled sheets which are used for the body of the ships and heavy machinery are called : DD11 , DD12 , DD13 , STW22 and STW 24 . Hard hot rolled sheets are used for making pressured pipes and oil tanks with standards of SPHT -1 , SPHT4 , SPHT -3 and SPHT -2 . Hot rolling sheets has lighter surface rather than cold rolling sheets .

The most significant difference between hot rolled sheets and other steel sheets is the color and appearance .

Hot rolled sheets are matt and in black while galvanized sheets and cold rolled sheets are bright .

Hot rolled sheets are available in different sizes and dimensions . Some of the most common sizes are :

Thickness : Between 1.5 to 100 mm .

Width : From 100 cm to 200 cm .

Length : No limit

Thickness of hot rolled sheets is from 1.5 mm up to 200 mm but Iranian factories produce them from 2 mm .

Note : Hot rolled sheets to thickness of 15 mm can be produced as roll or sheets and above 15 mm are only raw sheets . Both of these two forms are available in different sizes .

The physical dimension of hot rolled sheets : Hot rolled sheets are available in four thicknesses 100 , 125 , 150 , 200 with no limitation to length . Raw sheets depending on the amount of the order , any size and dimensions can be produced , but some dimensions are common and widely used . These dimensions are :

- Hot rolled sheet in 2000*1000 mm .

- Hot rolled sheet in 2500*1250 mm .

- Hot rolled sheet in 6000*1000 mm .

- Hot rolled sheet in 6000*1500 mm .

- Hot rolled sheet in 6000*2000 mm .

- Hot rolled sheet in 12000*2000 mm .

As mentioned earlier , this product is used as the primary material to produce industrial and constructional sections and it has significant importance for lots of industries such as :

• Agricultural devices

• Car industry

• Tanks in ship industry

• Oil pipes

• Guards and traffic equipment

• Building facilities such as profiles and bar girders

1. Molten slabs move forward to production line to the temperature of more than 1100°C by proper chemical analysis .

2. In the next step , thick oxide layers are eliminated .

3. After that , they are pressed to desired width and thickness by roll press machine .

4. After dimensions are determined , the reduction in the controlled thickness is carried out by rollers .

5. Slabs which are still molten , are collected in special coil boxes .

6. Coils opens

7. After that the second oxidation phase is performed .

8. Then again , the very strong hydraulic rollers work on the pieces which improves the mechanical properties .

9. The next step is to cool off the sheets .

10. The final stage involves packaging and printing the name of brand and factory and melting number . The last stage before submitting it to the warehouse or exiting the factory is to weigh the sheets .

In the following , we will introduce you top producers of hot rolled sheets .

Mobarakeh steel in Isfahan , Saba steel complex , Oxin steel in Khuzestan , Kavian steel , Gilan steel .

Mobarakeh steel co : It is one of the most important producers of hot rolled sheets in Iran , which is located 75 km far from Isfahan . This complex is the biggest industrial unit in Iran , which operates the steel slab production line , as well as , hot rolled sheet line . With more than 30 years of experience in the production of steel sheets , this company has allocated the production capacity of 11.3 million tons per year .

Oxin steel co : This factory , which is located within 10 km of the Bandar Imam in Ahvaz , is producing and offering high – quality hot rolled sheets . This company produces more than 1 tone of sheets per year .

Kavian steel co : This factory is located within 9 km of Ahvaz – Khuzestan road . The company found in 1993 and incorporated in Ahvaz steel in 1995 . Production made in this company can be used in ships , metal bridges , tanks and etc.

Gilan steel co : This company , which is located in Saravan road in Rasht , was found in 2003 and its products have applications in ship , constructional industries and pipes . As the first and largest steel factory in the private sector , the complex has a production capacity of 2.5 million tons of hot rolled products and 500 thousand tons of cold - rolled products annually .

According to the mentioned points , those wishing to use and obtain some information out hot rolled sheets should evaluate the applications using . As for example in some cases cold rolled sheets may be more proper , because hot rolled sheets are produced in higher temperature and as a result it has less accuracy . And in addition , the amount of used elements in steel influences on hardness of steel .

Ahan Pouya with more than a decade of best-selling experience, adheres to professional and ethical principles in the field of selling and buying at inside and outside the borders of Iran, helping you in the steel industry.