Abrasive WaterJet Cutting is one of the types of cutting machines. Water in English means water and , as it is known from the name of the device , Water Water is based on water . That 's why the cutting machine is also called water .

The function of this machine is that it will cut with high pressure in a narrow strip of water. In fact, this machine has a very strong water pump that will create a lot of pressure in the water.

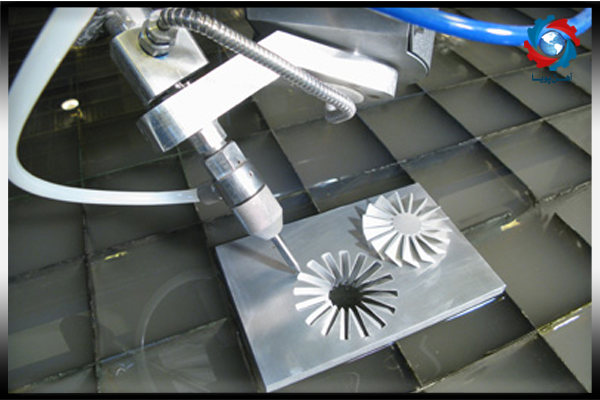

Therefore, when the machine is turned on, the water pump will enter it with very high pressure into the nozzle with a low diameter and at the same time a strong abrasive material called abrasive will be injected into the water to cut the hard materials.

Depending on the power of the pump, these materials are removed from the waterjet nozzle with variable pressures ranging from 4000 to 6200 and cut the desired design like other devices and of course with higher quality.

Each waterjet consists of several components :

The task of this pump is to prepare high-pressure water flow to enter the nozzle and have cutting power.

This device exists as an additional component in waterjets. The advantage of using these cut heads is to create precise angles in the desired designs, which will make things more beautiful.

As mentioned in the previous section, there is a nozzle inside the waterjet device through which water comes out of the device with a lot of pressure. Due to the need to increase the pressure and water force, the diameter of this nozzle must be very small in order to form a powerful blue fountain. Water will pass through a ventura after passing the nozzle, causing enough injected abrasive fine particles to be placed in all parts of the water stream to make a smooth cut. These materials pass through a special ceramic mix pipe and will be removed from the nozzle for high-speed cutting.

The device has a tank full of water that disperses abrasive jet energy through existing materials after cutting so that the device is not damaged .

The duty of abrasive shielding tank as well as abrasive flow control system is to measure the flow rate of abrasive particles.

The task of this system is to precisely control the precise vector movement of X-Y water outflow from the nozzle with high sensitivity so that the sections of the specific parts of the design are well done.

In fact, the motion controllers of abrasive waterjet systems are very advanced and work with computer programs. That's why even people who don't have enough skills to work with the waterjet machine can cut the parts with high precision and elegance.

The speed of waterjet machines available in the market to various items such as the structure of the material being cut, the thickness of that material, the expected cutting quality, the gaskets used, etc. depends . But in general, these devices can move at speeds of 0.1 to 3,000 inches per minute. They usually put speeds in place for these devices to cut a wide range of metals. The properties of components of each waterjet device such as the abrasion materials used, the size of the nozzle aperture, the cutting pressure, the focus of the cutting duct and the power of the pump used in waterjet can also affect the speed of this device.

You might be surprised if you know that waterjet with water power can cut any material with any hardness coefficient. Even this machine operates so powerfully that it is considered as the only cutting machine for super alloys and titanium . Also, some of the materials that produce harmful toxic fumes due to heat can be easily cut with it . Because the nature of the cutting by this machine is cold and unlike the devices that work with heat, no pollutants are removed from the cutting object.

This device has many advantages due to its high power and low pollution, some of the most important of which are :

1.Cutting all kinds of steel (Hardox Hardox, Hot Working, CK45) Titanium, Iron, Aluminum, Steel, Color Metal Cutting (Copper, Brass, Bronze), Cutting All Kinds of Sheet Metal, Plastic Cutting, Stone Cutting (Especially for Stone Mosaic), Polycarbonate Cutting, Acrylic Cutting, Parquet Cutting, Composite Cutting, Cutting All Kinds of Foam, Plexiglas Cutting, Ceramic Cutting, Tile Cutting, Glass Cutting, PVC Cutting, Wood Cutting .

2.The ability to cut super alloys that can't be cut with other devices .

3.Failure to create heat stresses that ruin cutting and poor quality of work .

4.High quality cutting edges and no need for polishing and re-machining to eliminate cutting defects .

5.feasibility of implementing complex projects .

6.Very precise and high cutting power .

7.Possibility of cutting steel up to 150 mm thickness and some other materials up to 500 mm thickness .

8.The high cutting accuracy of this machine is equal to 0.1 mm. (Gap cutting width or loss or feed of waterjet machine is also about 1 mm) .

As we said, the Waterjet machine works based on water pressure. Therefore, the higher the water pressure on the material, the more delicate grooves are created on the diameter of the cutting edges . As a result, the quality of cutting edges with this machine is directly related to water pressure. The lower the cutting speed, the higher the cutting quality of the edges and the more polished the edges will become .

The advanced Waterjet machine also has the power of 3D cutters, which is really amazing. But at the moment, these devices have not yet been used in Iran . For 3D incisions, the accuracy of the machine should be much higher than 2D cutting machines . For this reason, they are only used to produce very specific tasks, and there are limitations in this regard that, unlike the 2D mode, they have not yet been able to create the capability to cut any type of design.

It has applications in many cases , the most common of which are :

Because waterjet machines have the ability to cut even very complex designs, they are widely used to make sophisticated decorative appliances. Basically, this machine is known in art and architecture for performing a variety of lattice and mosaic cuts on various materials, especially stone and ceramics. Of course, it is more capable than that and these are just examples to get to know you more.

Due to the high precision of this machine in cutting, in the industry they usually use waterjet cutting to create precise sizes in primary productions with limited circulation. They will then mass produce those parts with other devices.

Ahan Pouya with more than a decade of best-selling experience, adheres to professional and ethical principles in the field of selling and buying at inside and outside the borders of Iran, helping you in the steel industry.