Concrete is one of the most widely used building materials in today’s world. It is a mixture of cement, water, and aggregates (such as sand and gravel), which hardens into a strong and durable substance through a chemical reaction between water and cement. Due to its high strength, long lifespan, easy availability of raw materials, and low cost of production, concrete plays a key role in civil, industrial, and architectural projects.

Ready-mix concrete is a type of concrete that is manufactured in specialized batching plants using precise and controlled equipment. It is then transported to the construction site using special trucks called transit mixers. Unlike traditional on-site mixed concrete, ready-mix concrete offers superior quality, strength, and uniformity. It can also contain specific additives to improve performance for particular applications.

Standard Concrete

Architectural Concrete

Fiber-Reinforced Concrete

Flowable Concrete

Precast Concrete

High-Density Concrete

Self-Compacting Concrete (SCC)

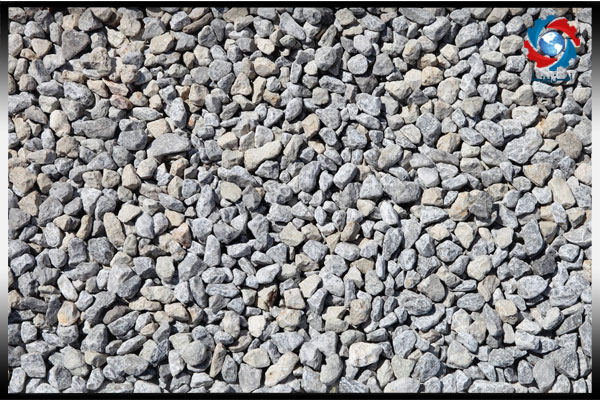

Aggregate selection and preparation

Procurement of Portland cement

Dry mixing of materials in the mixer

Transportation via conveyor belts

Addition of water and admixtures

Final mixing in the main mixer

Quality control and dispatch to site

To regulate the setting time

To increase durability

To improve freeze-thaw resistance

To mitigate alkali-aggregate reactions

To enhance workability and placement

Plasticizers

Superplasticizers

Anti-freeze admixtures

Retarders

Accelerators

Bonding agents

Waterproofing agents

Air-entraining agents

Mold release oils

Pozzolanic mineral additives

Air-entraining agents: Improve resistance against freezing and thawing

Mineral additives: Improve density, color, and durability

Retarders: Useful in hot climates and for long-distance transport

From ancient Rome to modern Iran, concrete has played a vital role in architectural and construction practices. The widespread use of Portland cement in the 20th century revolutionized the concrete industry and enabled the construction of massive infrastructure projects.

After the materials inside the mixer have been obtained within a certain period of time, then transfer them to a hopper on a plastic strip. This plastic strip prevents waste of the resulting materials.

Precise quality control

Faster execution

Lower risk of human error

Higher durability and reliability

The selection of the appropriate type of concrete depends on the structure type, local climate, and delivery distance. Proper selection directly impacts the lifespan and performance of the structure.

Bridges

Dams

Tunnels and subways

High-rise buildings

Foundations and basements

With its high density and thermal mass, concrete can act as insulation against heat and cold, reducing energy consumption in buildings. It is an excellent material for energy-efficient design.

In modern factories, leftover concrete is recycled into reusable aggregates. This reduces construction costs and conserves natural resources while supporting sustainable construction practices.

Keep freshly poured concrete moist

Use covers and mist sprays

Prevent rapid water evaporation

Monitor ambient temperature during early curing days

Geopolymer Concrete: Cement-free and heat-resistant

Smart Concrete: Capable of self-healing cracks

Lightweight Concrete: Ideal for high-rise and earthquake-prone regions

Digital concrete mixers

Automated batching systems

Temperature and humidity sensors

Artificial intelligence for mix design optimization

ASTM C94 – USA

EN 206 – Europe

ISIRI 3203 – Iran

Concrete plays a crucial role in large-scale infrastructure projects such as railways, stations, airports, seaports, and underpasses. These structures require high-performance concrete that can withstand thermal stress, moisture, and heavy traffic loads.

In subway construction, waterproof and pressure-resistant concrete is vital. In coastal areas, concrete must be resistant to saltwater corrosion, often achieved with specialized admixtures.

Concrete plays a crucial role in large-scale infrastructure projects such as railways, stations, airports, seaports, and underpasses. These structures require high-performance concrete that can withstand thermal stress, moisture, and heavy traffic loads.

In subway construction, waterproof and pressure-resistant concrete is vital. In coastal areas, concrete must be resistant to saltwater corrosion, often achieved with specialized admixtures.

Eco-friendly concrete is essential for green building practices. These concretes use recycled materials, mineral admixtures, and less water, reducing carbon footprint and energy waste.

High-performance concrete in green projects increases structural lifespan and reduces maintenance and reconstruction costs. It also helps earn certifications like LEED (Leadership in Energy and Environmental Design).

Many old buildings in Iran and elsewhere don’t meet modern safety standards. Retrofitting using reinforced concrete, polymer adhesives, and shotcrete can significantly strengthen such structures.

Columns, beams, and foundations are reinforced to resist earthquakes, erosion, and increased loading. This is a faster and more cost-effective method compared to demolition and reconstruction

:Climate conditions directly affect the type of concrete mix used

Cold regions: Use anti-freeze and retarders

Hot and dry regions: Require high workability and controlled setting time

Coastal areas: Need corrosion-resistant concrete to withstand salt and humidity

Proper adaptation increases service life and reduces maintenance costs

Concrete isn’t just structural—it also reduces noise and thermal loss. Special acoustic concrete is used in modern buildings to limit sound transmission between spaces

Lightweight insulating concrete can significantly reduce thermal energy loss, making it a smart choice for energy-efficient buildings

Adding extra water on-site to improve flow

Not using vibrators for proper compaction

Pouring during the hottest time of day without protection

Ignoring proper curing and allowing surface to dry too fast

Training laborers and on-site supervision are essential to avoid such mistakes

With growing demand for intelligent buildings, concrete is undergoing major innovation. Examples include

Ultra-High Performance Concrete (UHPC)

3D-Printed Concrete

Bio-based Concrete

These advanced concretes feature self-healing properties, pollution absorption, and low energy usage—revolutionizing the future of construction

Smart concretes equipped with internal sensors allow real-time monitoring of stress, temperature, and humidity. Meanwhile, incorporating recycled materials supports sustainable and waste-reducing building methods

In today’s world, concrete is not just a construction material—it’s a driver of sustainable development. Understanding its types, additives, production stages, and optimization methods helps engineers, contractors, and developers build stronger, safer, and more cost-effective projects

By choosing the right ready-mix supplier and leveraging modern technologies, you can reduce construction costs, increase efficiency, and help protect the environment.

Ahan Pouya with more than a decade of best-selling experience, adheres to professional and ethical principles in the field of selling and buying at inside and outside the borders of Iran, helping you in the steel industry.