Cold sheet refers to sheets created by cold rolling and black sheet (hot sheet) refers to sheets produced by hot rolling.

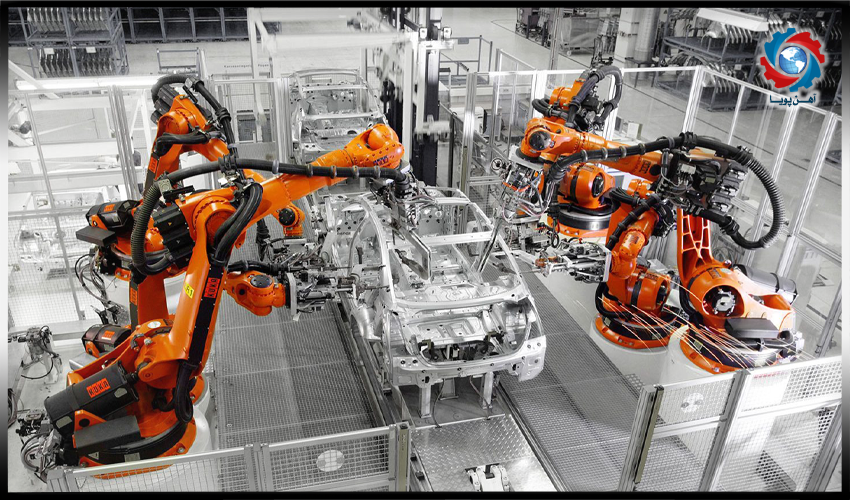

In the industry, high-thickness sheets are converted to lower thicknesses by cold rolling, and for this reason, the appearance quality of cold-rolled sheets, including galvanized sheets and oil sheets, is very suitable. due to the proper appearance of most applications of these cards in appearance related work . They include automotive industry , office furniture , home appliances , building types , construction of inflexible panels , building materials .

The most important advantage of galvanized sheet and oil sheet called cold sheet is the extraordinary resistance of these sheets against high pressures. In practice , the building engineers will use this type of products to manufacture materials with high resistance and use less material . These are not only the distinguishing characteristics of those cards and the high variation in color and size makes these products be used in producing many kinds of products ranging from car industry to household appliances and construction materials .

Cold sheets available in the market, including galvanized and oiled sheets, have a width between 125-100 cm and a thickness of 3-0.3 mm as standard. In general , these cards are produced in different sizes and do not change after their apparent shape processing .

The cold sheet is divided into three categories depending on the type of alloy used :

1.Normal st12

2.Half traction st13

3.Above traction st14

In commercial markets , oil cards are known as cold cards . The main reason behind these cards is its apparent form , which distinguishes it from other cards . This group of sheets is produced with cold rolling technology and due to protection and prevention of rust, oil is applied on it as a protector to prevent rust when it is delivered to the customer.

Oil sheet is the basis for the production of galvanized sheet, which is added to the galvanized coating using various coating methods. Galvanized coating is a coating of zinc metal that prevents corrosion of the sheet. Galvanized sheet in industry in thicknesses of 5-0.8 mm is produced in factories such as Mobarakeh Steel of Isfahan.

Galvanized sheet is the basis for the production of colored sheets that are added with various technologies in the form of pre-kiln paint. The main uses of these cards are mostly in the roof of the roof , auto industry , and the exterior facade of the buildings .

Hot rolled sheet can be used as a finished product on the market, but in industries such as automobiles, home industries, etc., this type of product can not be used. For this reason, it is necessary to perform operations such as cold rolling on this type of sheet in such a way that the sheets obtained by hot rolling are reduced in thickness after being washed in acid (for deoxidation) and passing through several four-roller shelves. Reduction of sheet thickness in cold rolling, especially galvanized and oiled sheet is done by one or more reciprocating rolling racks or several tandem (series) rolling racks. Each rolling rack includes a steel frame in which the roller bearings are housed and withstand the force applied to the bearings by the rolling force. In order to reduce power and power , the precision and uniformity of the thin sheets thickness is used in the four - order cabinets .

1 - Casting

2.Preheated oven

3.Hot rolled

4.Pickling

5.Cold rolling

6.Anilling

7.Temper Mill

Ahan Pouya with more than a decade of best-selling experience, adheres to professional and ethical principles in the field of selling and buying at inside and outside the borders of Iran, helping you in the steel industry.