Ingots are a part of metallic materials which are made by melting different kinds of metals . In this article we will discuss about steel ingots and their properties .

Ingots are a part of metallic materials which are made by melting different kinds of metals such as gold , steel , tin , aluminum , bras , copper . The production process of ingots is thousands of years old because casting makes metals easy to transfer or mold or save . Production of ingots actually is one of the intermediate beams that calculates as the primary material of down-stream industries .

Pure molten metal will pour in the templates as bars or solid blocks then Ingots are carried out by freezing the molten metal removed from templates . It follows some aims .

Ingots have the template less than 2 meters and the cross-sectional area of them are circular . Ingots will be formed in desired forms during further processes .

Ingot refers to the sections with a cross-section of 225 square centimeters and smaller sections are referred to as billet .

The first important problem is the shape and dimensions of ingots which is important for the later stages of the forming processes .

The next point to take care is the way that molten materials put in the templates as it determines the physical and mechanical properties of the final sections .

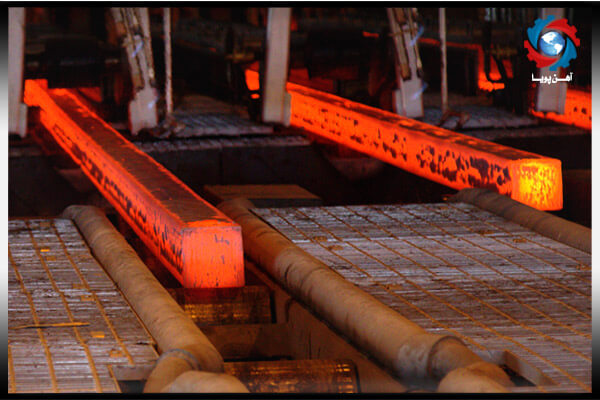

After the conversion of iron ores to raw steel or sponge iron , after the production of molten steel in convertor , steel ingots shape . Steel ingots are supplied as precast products with different shapes for various uses such as ingot , billet , bloom and slab .

Ingots are rectangular pieces that often have trapezius cross-sections due to ease of removal from templates and ease of transfer . The length of each bar is maximum 2 meters . It is generally produced in small workshops .

In large steel industries‘’steel ingots’’ are referred to asbloom , billet or slab .

In addition , steel ingots has different grades such as 3SP- 5SP ( Russian standard ) or ST37-ST52 ( Germany standard ) ranging from different percentages of materials with different mechanical properties such as flexibility , bending , stretching and turning and has a variety of usages .

Billet is a long steel ingot which its cross-section is circular or square .

Bloom is another subcategory of steel ingots which has 15 cm long and cross-section of 230 cm .

Slab has a rectangular surface and produced directly through casting or indirectly through warm beaming from every other ingots .

Iron extracts from iron ores by different methods such as blast furnace , direct reduction or tunnel furnace .

It is important to know that iron ore is the main material ofsteelproduction . A difficult way should be passed toproduce steel . Most of the irons used in the world are made through blast furnaces .

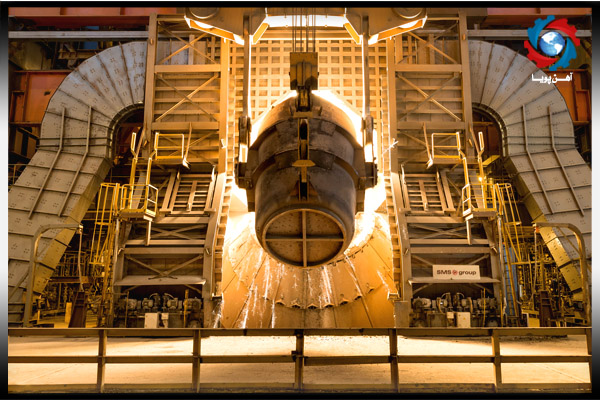

In this furnaces coke and lime must be added to the furnace so that iron and cast iron separates from iron ores .

Then raw iron converts to molten steel . After raw steel extracted from EAF , ingot production starts . It is important to cast and create the templates of ingots because , microstructure ( interior order ) of pieces forms here in this phase and mechanical and physical properties of other products are dependent on this step . After cooling , steel ingots are cut over to the desired lengths .

Most of the steel used in the world is produced throughblast furnacesbut here in Iran we do useelectric furnaces .

In electric furnaces firstly scraps enter the furnace . During scraps melt , a combination of sponge iron and some materials such as coke , bentonite , lime and other additional materials adds and Then oxygen lancing carries out . Then steel turns to molten maerials and finally in casting unit , by using cool water steel ingots shape .

Capacity of electric furnaces are varied from 1 kg to almost 20 tones . For example , Kavir steel co. in Kashan uses electric arc furnace that has so much difference with ingots produced in other furnaces .

The most important application of bloom and billets is in the production of wires , girders , rebars , angels , channel beams , tee joints , channel sections , weldless tubes and mannesmans .

Blooms which are one of the most important products of raw steel are used as primary materials ofcold and warm beam( to produce metallic sheets , metallic strips , coils as well as weldless tubes , normal tubes and etc.)

In Iran companies such as Mobarakeh steel co. Khoozestan steel and Chadormaloo co. produce raw steel by using electric furnaces and produce ingots and metallic sheets .

Mobarakeh steel co. exclusively produces slabs and other manufacturers of Iran International steel and Khoozestan steel co. , they produce all types of bloom , bellit and slabs .

Zob-Ahan co. utilizes blast furnaces and only produces bloom . Other small workshops on the country also useinduction furnacesin order to reach raw steel .

Carbonexisting in ingots and its analyze is more important to produce each kind of rebar . To produce rebar with dimensions of 14-40 , ingots with carbon of 30 to 35 is needed . For lower dimensions , ingots with lower amount of carbon is needed due to softness and stretch .

Ingots 150 and 125 or 130 are similar to produce rebar but ingot 150 is more useful than others . Some manufacturers use only ingots 125 and some modern manufacturers use both .

The new high-tech production line in bigger modern manufacturers use both ingots and may use ingots 120 and 130 for little rebar and ingot 150 for large rebar .

Some production lines are designed so that they can produce little rebar with ingot 150 .

Overally speaking ingot 100 , 120 , 125 , 130 , 150 and 160 is calledbillet and ingot with bigger sizes such as180*180 , 200*200 and 250*250 is called bloom . Blooms are used to produce industrial rebars .

Scraps use direct reduction method to produce ingots . But sources of scraps are limited so that sponge iron is used instead of scraps . However there is a direct connection for these products which has some limitations and a specific framework .

There are three types of fabric , bloom and CCM .

Ingots made in electric arc furnaces have better quality rather than electric furnaces because there are one more step of analyzing .

Ahan Pouya with more than a decade of best-selling experience, adheres to professional and ethical principles in the field of selling and buying at inside and outside the borders of Iran, helping you in the steel industry.