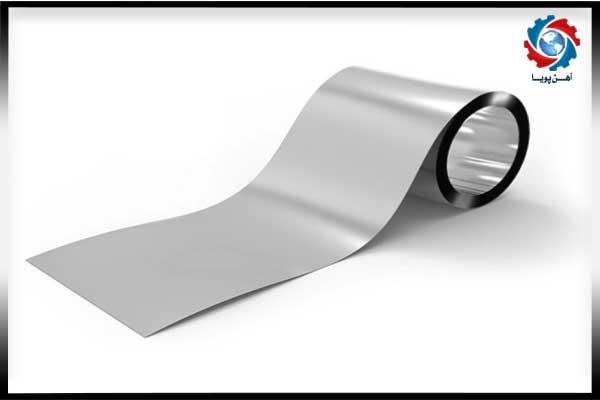

In the metal, mechanical, and construction industries, precision in the installation, alignment, and positioning of components plays a crucial role in the final performance of equipment. One of the simplest yet highly effective tools in this regard is the Laton sheet. These thin metal sheets are commonly used as spacers, shim plates, or leveling aids in various sensitive and industrial projects

Laton sheets are usually made from durable and resistant metals such as stainless steel, copper, brass, and Monel. Due to their minimal thickness, they play a key role in maintaining precise spacing, preventing metal-to-metal contact, and increasing the lifespan of equipment

his article provides a comprehensive overview of the types of Laton sheets, technical specifications, applications, advantages, manufacturing standards, and key factors to consider when selecting and purchasing them

A Laton sheet, also known as a “precision metal shim,” is a thin and flexible sheet used for aligning components, preventing wear, sealing, and maintaining accurate spacing between two metallic or mechanical surfaces. These sheets are critical in high-precision industries such as oil & gas, power plants, automotive, aerospace, medical equipment, and industrial tooling

Laton sheets typically range in thickness from 0.05 mm to 5 mm and are available either in rolls or pre-cut sheet formats. The suitable thickness depends on the required precision, the type of industry, and the amount of pressure applied to the components

.One of the most durable and widely used types of Laton sheets is made of stainless steel, available in industrial grades such as 304, 316, 321, and 430

Corrosion resistance against rust, acids, and chemicals

High thermal resistance

Long lifespan in humid or corrosive industrial environments

1.Flange assembly in oil and gas facilities

2.Industrial washers

3.High-pressure sealing equipment

4.Marine anti-corrosion structures

This sheet is made from pure copper or copper alloys and is widely used in specialized industries due to its high electrical and thermal conductivity.

Excellent electrical conductivity

Corrosion and oxidation resistance

High malleability and formability

Electronic circuit boards

Transformers

Heat exchangers

Thermal transfer tubes

Aerospace and automotive industries

Monel is an alloy composed primarily of nickel and copper, offering exceptional resistance to extremely corrosive environments, including marine applications

Resistant to acids and salts

Corrosion-proof in moist environments

Mechanical stability under high pressure

Marine industries (shipbuilding, port equipment)

Corrosive fluid transfer systems

Oil and gas drilling equipment

.These sheets are made from copper-zinc (brass) or copper-tin (bronze) alloys and are more commonly used in decorative and electronic applications

Aesthetic appearance with golden or bronze color

High malleability

Moderate electrical conductivity

Decorative equipment

Lightweight mechanical parts

Home appliances

Musical instruments and precision tools

Petrochemical, Oil & Gas

In these industries, high pressure, temperature variations, and corrosive chemicals are common. Using resistant sheets like stainless steel, Monel, or sometimes aluminum Laton with high dimensional accuracy is essential.

Automotive Industry

Precise spacing between components is crucial in engines, suspension systems, and assembly parts. Laton sheets play a critical role in areas such as chassis, gearbox, and engine components

In sensitive electronic equipment, thin copper Laton sheets are used for current transmission, noise shielding, and vibration control.

Laton sheets must comply with specific standards depending on their intended use. These include:

ASTM B36 / B152 for copper sheets

ASTM A240 for stainless steel sheets

AMS and MIL-STD for military and aerospace applications

DIN EN 10151 for spring and precision sheets

These standards ensure the final product meets industrial requirements for dimensional accuracy, surface quality, chemical composition, and mechanical resistance

1.High precision in aligning and installing industrial equipment

2.Extended lifespan of machinery and parts

3.Prevention of direct metal-to-metal contact (reduces corrosion and friction)

4.Reusability if undamaged

5.Lower maintenance and repair costs

6.Lightweight and easy to cut and install

Material Type: Choose the metal type (steel, copper, brass, Monel) based on the working environment

Thickness: Determine the exact sheet thickness depending on pressure, force, and required precision

?Application Needs: Do you need conductivity? Acid resistance? High formability

:The price of Laton sheets depends on several factors. Understanding them can help buyers make cost-effective and strategic decisions

Base Metal Type: The material is the most influential pricing factor. For instance, copper or Monel sheets are pricier than steel or brass

Thickness and Dimensions: Thicker or larger sheets cost more. Custom orders can also be more expensive

Grade and Manufacturing Quality: Precision tolerance, annealing, and surface finishing increase final costs

Metal Market Fluctuations: Global metal prices, exchange rates, and local market conditions directly impact Laton sheet prices

Brand and Country of Origin: Well-known foreign brands are typically more expensive but offer higher quality

Customization Requests: Punching, laser cutting, or special packaging add to the cost

Order Quantity: Bulk orders usually qualify for discounts and are more economical

Laton sheet is a type of thin, precision metal sheet used for alignment, spacing, sealing, and increasing the longevity of industrial components in various sectors. By understanding its characteristics, standards, and pricing factors, one can make a precise, economical, and project-specific selection

Ahan Pouya with more than a decade of best-selling experience, adheres to professional and ethical principles in the field of selling and buying at inside and outside the borders of Iran, helping you in the steel industry.