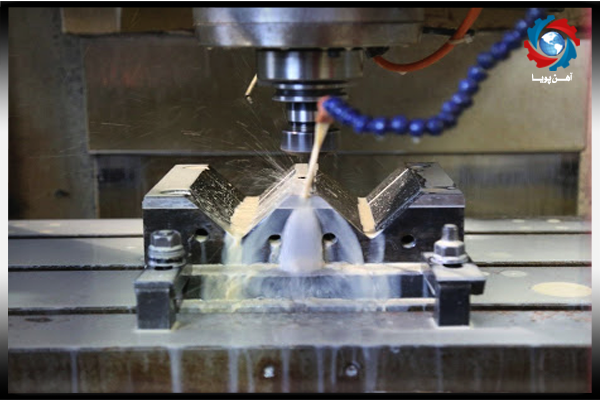

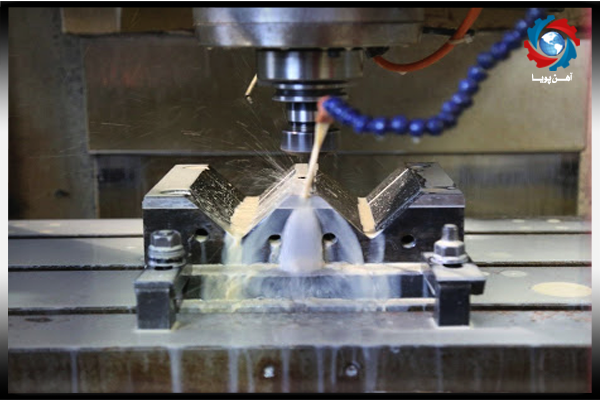

Today, one of the most important and widely used jobs in the industry is mold making. The nature of this job is to make all kinds of parts in different dimensions and different materials.

Molding operations go back to very distant years, when molding was done with very large stone molds. Gradually, the molding industry made significant progress, so that in 1872, the first advanced industrial molding machine was invented and built.

There are several methods used to make different molds with different materials. Each piece has its own unique and special method due to its material and structural complexity. In general, industrial molds are divided into different categories according to the type of use, appearance and material of their materials, which we will examine the types of industrial molds together in the following.

Casting molds are one of the most widely used molds in various industries, which according to their type of material, three methods of die-casting, gravel and sand can be used to make them. The die-casting method is used for further fabrication of aluminum parts with a thickness of 1.5 to 15 mm. They also use the die method to make a variety of parts that have different thicknesses and do not have the same thickness, and finally the sand method is the most common method in the industry for making metal parts.

Forging molds are another type of industrial molds that are made of steel and very strong steel molds with high toughness are used to shape them. Toughness means the ability of the dough to deform before failure occurs in the material. Forging molds have 3 different models, which are: closed forging mold, open forging mold and closed forging mold.

Wood molds are one of the oldest types of molds that humans have used since ancient times. In this type of molds, usually boards made of coniferous trees such as pine and cypress, as well as broadleaf trees such as sycamore, oak, spruce, etc. are used. Due to the greater resistance of coniferous wood to moisture, molds made with these woods are more suitable for wood molding than molds made of broadleaf wood.

Ahan Pouya with more than a decade of best-selling experience, adheres to professional and ethical principles in the field of selling and buying at inside and outside the borders of Iran, helping you in the steel industry.