Rebar is one of the steel sections which is almost one of the most applicable iron products in any construction project. The manufacture of rebar in a variety of grades, thicknesses with different treads has multiplied the advantages and applications of this product.

Accordingly, rebar issues such as its principled use in a variety of parts of the building are very important because in case of improper use of it, it may incur multiple and exorbitant costs for the consumer. Another important issue is the purchase of rebar from reputable vendors. Because it is important to use healthy sections without rust or bending.

In this regard, Iron Center trading with more than 30 years of experience is proud to offer rebar prices and sell it with excellent conditions to our dear customers. In the following, we will examine the specialized method of nailing the earth, which is somehow a method of stabilization of excavation.

1.Stabilizing the land of the Gazans

2.Stabilizing cuts on railways or highways

3.Tunnel doorways on steep slopes and unstable layers

4.Excavation of guard buildings as well as for high-rise buildings and underground installations

1.In the first and most basic stage of the work, the type of soil must be determined by the specialist.

2.Then, according to the type of soil up to a depth of 1 to 2.5 meters above ground should be excavated.

3.In the third stage, the drilling machine performs excavation at an angle of 15 degrees from the horizon.

4.Now, according to the above, the rebar is brokered inside the soil.

5.Slurry is injected.

6.This step is time to install drainage tapes.

7.Finally, concrete spraying takes place.

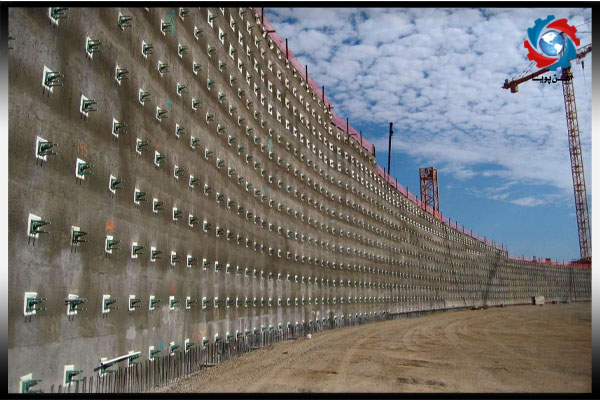

8.Now the steel plates are placed on the concrete surface and screwed to the end of the reinforcement.

Shields are constructed by drift or vibration of prefabricated parts into the ground. Although it is a range of materials such as timber, steel and prefabricated concrete are used as shields, steel shields are the most common.

This system is usually applicable for temporary sealing of the pit. If the shields are not recyclable, they are very costly. It is relatively easy to install this bracing system in sandy and clay soils, regardless of the depth of the aquefer.

Installing in soils containing rubble and larger stones may be very difficult or impossible. Steel shields are easily flexible. If the protection of the adjacent area of the excavation is necessary, only low excavation heights can be supported by this method without inhibition.

The guard candle and boarding system is used to build temporary or permanent structures as well as to prevent collisions with underground facilities during rebar nailing in the soil. It is usually more common to use this system in places where the water level is lower than the excavation site. In this way, the beds are planted between the guards' beams and then they provide support using steel sections.

Basically, in deep excavations, the dug-out candle wall system uses concrete piles, while the carved candle wall system is used in cases where the application of bracing on the soil surface is not possible or the use of guard beams or special shields in the soil is hard to use.

Diaphragm walls are used in excavations lower than groundwater aquifers in soft soil areas. Aperture walls are implemented as adjacent trenches each with a thickness of approximately 600-900 mm and a height of approximately twice the depth of the pit.

First, a trench is drilled into the ground and pumped into it at the same time as drilling the slurry to prevent the collapse and blockage of the trench and maintain its stability.

Before concrete, rebar shelves are placed in a drilled groove filled with drilling mud. The concrete is poured from the bottom up and replaced with bentonite mud pumping outwards, and this cycle is repeated until the trenches are fully concreted.

This method is one of the most suitable and common methods of implementation of guard structure in urban areas. Its implementation is simple and does not require high equipment and expertise, and at the same time it has a lot of flexibility in different conditions in terms of implementation.

In order to implement this type of guard structure, wells are first drilled in the place of vertical members of the truss which are located in the vicinity of the pit wall. The depth of these wells is equal to the depth of the pit plus an extra value for the execution of the inferior end pile of the truss member. Then the reinforcement is placed inside the candle and the vertical member is placed inside the pile and then this well is concreted.

Ahan Pouya with more than a decade of best-selling experience, adheres to professional and ethical principles in the field of selling and buying at inside and outside the borders of Iran, helping you in the steel industry.