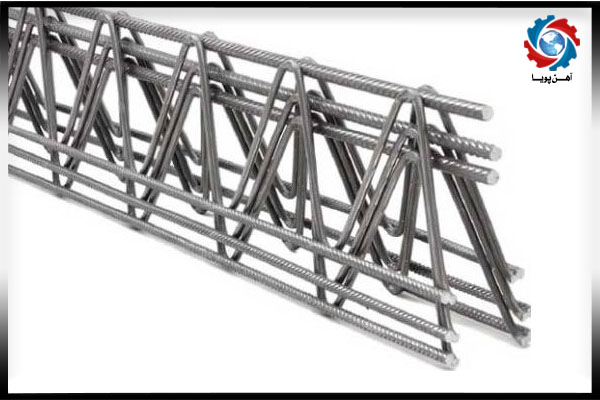

One of the types of rebar is zigzag rebar, which is made of a3 ribbed rebars and simple rebars. The way these rebars are connected to each other is more welded and sometimes connected by hooking these bars together. This type of rebar has many uses in the construction industry .

In the construction industry, this type of rebar is used as a member with high loading. Ribbed bars can produce different lengths and widths according to their usage type. These rebars, because they have a lot of bearing properties, are mostly used in the construction of roofs .

Zigzag rebar is produced prefabricated and consists of three different parts: high rebar , transverse rebar and low rebar.

Since zigzag bars are made of ribbed rebar, then all the characteristics of ribbed rebar can be extended to these bars, except that the diameter of ribbed rebars is usually a number between 6 and 16 mm, but the diameter of zigzag bars is generally 4 mm.

1.Manual method

If we want our rebars to have a triangular surface, we need three ribbed rebars and smooth bars. In this method, we first put the ribbed bars together and mark it according to the length we need. Now, with special cutting machines, cut the location of the signs.

In the next step, we bend the simple bars between transverse and ribbed bars to V mode. Finally, we weld these rebars in their own place. The production of zigzag rebar manually requires a lot of time and workforce.

2.Mechanized Method

In this method, zigzag rebar is produced only with the help of a workforce and machine. In the mechanized method, longitudtory bars are first coiled on each other and smoothed by a special device. These rebars are under great tension and bend as v. In the next step, these sections are electrically connected by reinforcements and boiling point.

The zigzag rebar made in this method initially has very long lengths, and then is cut according to the type and size required. The zigzag rebar produced by mechanized method has a much better quality and higher quality than the zigzag rebar produced manually.

This type of rebar has different applications in various industries due to its unique characteristics, the most important of which are :

1.Design of truss types

2.Making joists

3.Use in the roof of the types of structures and most concrete structures

4.Construction of bridges

5.Design and manufacture of all kinds of underpasses

6.In the skeleton of a variety of steel structures

Ahan Pouya with more than a decade of best-selling experience, adheres to professional and ethical principles in the field of selling and buying at inside and outside the borders of Iran, helping you in the steel industry.