The rebar is one of the most widely consumed material in the construction industry Which plays an important role in the structure of the building. Sections that are made of circular steels and have different diameters and widths are called rebars. This product is produced in two types, simple and ribbed. The standard diameter of this product is usually between 6 to 60 mm, in Iran diameters between 6 to 32 mm are easily available and for larger diameters should be ordered from the manufacturer. The typical length of this product is 12 meters and the branch is, but its production is also available in coils if its diameter is less than 10 mm.

It can be cut in two ways , including the cold method and the warm method .

The cold cutting method is better for the rebar and retains its properties And it affects the quality of the product .

To use the cold method, you should pay attention to the weight of the rebar and choose the best cutting method according to its weight, size and dimensions. In cold cutting , the heat is not directly in contact with the product And the product is cut to the desired size. Cutting machines such as water jet, band saw, disc saw, hand saw, crank saw work by cold cutting method.

There are advantages and disadvantages to which we can use these methods depending on what we have Features such as :

1.No change in the molecular structure of metals

2.Ability to cut sections in different sizes and shapes

3.waste reduction

4.Suitable Surface Quality

5.Identical parts

6.Non - production of toxic gases

7.more flexibility

A great revolution emerged when the machine was created in the cutting industry . Because it can cut thick pieces with high precision. The advantages of this machine include the ability to program, make cuts fully automatically, angular cutting of parts, reducing waste while working and… . The band saw rotates its axes with the help of an electric motor and moves the part using a hydraulic jack to make the cut.

This machine replaces the high-risk fire saw machine, which has high safety and higher quality during operation. This machine has various blades that can easily cut metals .

This device is less accurate than the previous two devices and produces more waste. Move this machine when cutting by going back and forth on the piece. The product is less used for its type of performance as compared to other devices .

The simplest device for cutting rebar is the most common tools in the cutting field . Saws come in the same size with different teeth. If the rebar is thin, it is cut with small serrated saws, and if it is large, it is cut with large saws. The force of the human hand is very important to this machine and dividing the pieces into two equal parts . Of course , it has to be noted that this means a lot of dangers while working for humans And safety equipment must be accompanied during work Because there is a possibility of warping or breaking the blade and.

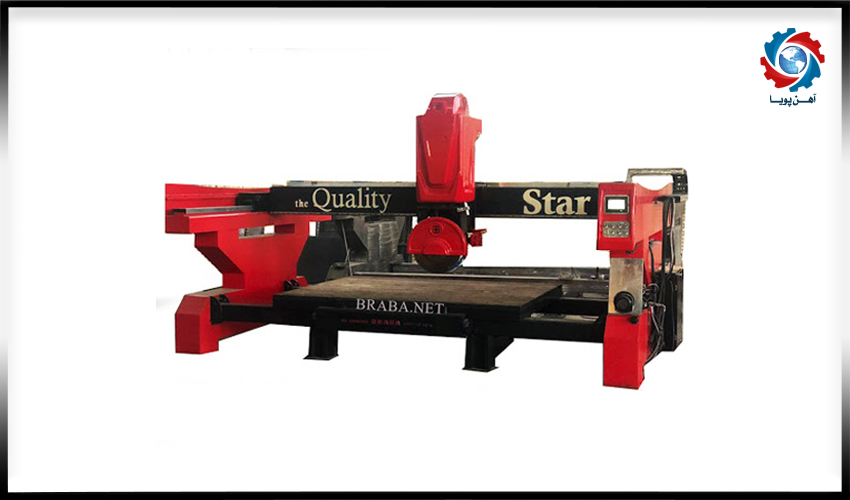

Water jet cutting machine performs cutting operations of hard materials with the help of high pressure water motors. However , this machine is currently used mostly for rock cutting and does not use it much to cut rebar and metals . But it works very well in cutting hard materials . The precision and speed of this machine and the automated work of his work has led to a large number of fans at large .

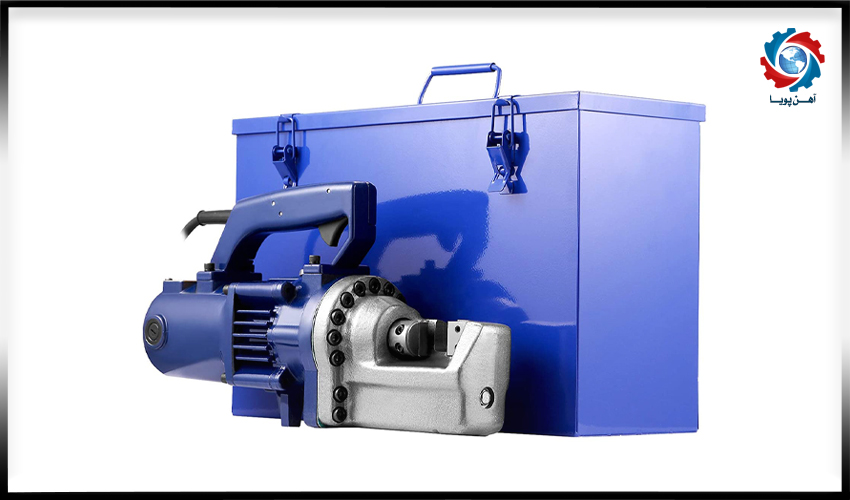

When required to have a machine that has a high speed and cut a large number of rebar at the lowest point , it has to be used . One of the suitable features of this device is having a wheel under the scissors, which makes it easy to move. Rebars up to 35 in diameter are cut with this machine in two ways, manual and electric.

In order for the rebars to be used in construction longitudinally and transversely, it is necessary to make the rebars themselves in order to use them in connection and reinforcement for concrete structures. Khamoot is a type of transverse reinforcement whose task is to increase the building's resistance to shear and torsional forces. The spinning machine can automatically and semi-automatically change the shape and cut the rebar into rectangles or rounds.

This machine can cut smooth rebars up to size 50 and ribbed rebars up to size 45. This machine can maintain the standard of parts and cutting.

This wrench is one of the most simple means of bending the thin rods . ذThis device is made of hard steel to be able to withstand the pressure on the iron when bending. The opening of the wrench should be in harmony with the diameter of the product so that the product can be fastened to the wrench in the best possible way for easy and quality bending.

In this machine, the cutting operation is performed by rays that use laser rays to burn, melt and sublimate. There are different types of lasers such as gas, chemical, solid, fibrous and که, of which only solid and gas lasers are used for industry and metal cutting. Lasers have the least damage to metals in the hot cutting method.

Ahan Pouya with more than a decade of best-selling experience, adheres to professional and ethical principles in the field of selling and buying at inside and outside the borders of Iran, helping you in the steel industry.