In construction processes, one of the most important factors for achieving a durable structure is ensuring the correct concrete cover over the rebar. Inadequate cover can lead to rebar corrosion, structural weakening, and eventual deterioration over time. This is where a concrete spacer, also known as a rebar spacer, plays a vital role. This simple yet essential component ensures that the rebars are held in the correct position and that the proper concrete cover is maintained.

In this article, we will provide a comprehensive overview of spacers, their types, applications, benefits, and execution tips to help you make better decisions in construction projects.

A spacer is a component used to maintain a specific distance between the rebar and the concrete formwork. The primary goal is to ensure the required thickness of concrete cover and prevent direct contact between the rebar and the concrete surface. Spacers are usually made of plastic, concrete, or metal, and they come in various shapes and sizes to meet different project needs.

Proper concrete cover over rebars is crucial for several reasons:

Direct exposure of rebar to external elements such as moisture and chemicals can lead to rusting and reduced lifespan of the structure.

Accurate placement of rebar within the concrete ensures the desired tensile and bending strength of the structure.

Spacers help maintain the stability and alignment of rebar during pouring, resulting in consistent concrete cover.

Spacers are designed based on their application, location of use, and load-bearing requirements:

The most commonly used type, available in various sizes and shapes. Their advantages include low weight, affordability, and easy installation. Ideal for light structures like non-load-bearing walls and slabs.

Used in heavy-load projects or where the spacer must be compatible with the concrete (e.g., tunnels, industrial structures). They offer high strength and full compatibility with concrete.

Less common but useful in special cases such as high-temperature environments or heavy load-bearing conditions. Usually made of galvanized steel.

Spacer Classification by Use Location:

Base Spacers (with feet): For slabs, foundations, and floors

Wall Spacers (with back support): Designed for vertical walls and formworks

Ceiling Spacers: Used in waffle or joist slab ceilings

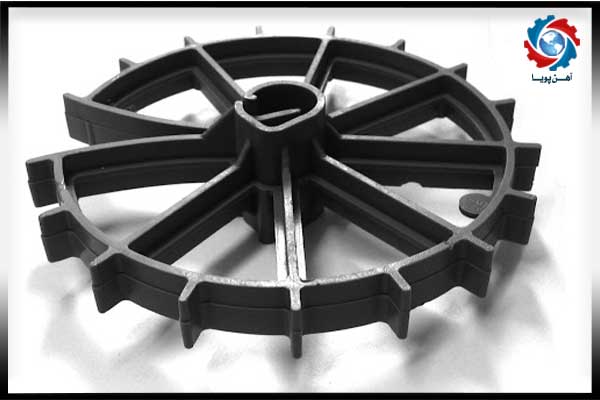

Ring Spacers: Ideal for columns or round sections

Foundations and Footings: Prevent rebar settlement at the bottom

Walls and Columns: Ensure correct cover in vertical forms

Ceilings: Keep rebar in upper positions during pouring

Tunnels and Underground Structures: Require durable and high-load spacers

Residential and Commercial Buildings: Widely used due to ease of use and affordability

A high-performance spacer must possess the following features:

Sufficient compressive strength to withstand concrete pressure

Compatibility with concrete and no negative effect on its strength

Resistance to environmental conditions (moisture, heat, chemicals)

Easy and quick installation

Design tailored to rebar size and formwork type

By providing standard concrete cover, premature damage to rebars is avoided.

Spacers hold rebars in position and reduce the need for constant adjustments.

They prevent direct contact between rebar and formwork, ensuring uniform pouring.

Inspectors can easily verify correct rebar placement through visible spacers.

Suitability for Rebar and Structure: Choose based on rebar diameter and required cover thickness.

Sufficient Quantity: Insufficient use can reduce concrete quality. Typically, 4–6 spacers per square meter are needed.

Proper Load Resistance: Especially important in foundations and columns.

Avoid Unapproved Alternatives: Using stones, bricks, or wood as spacers is highly non-standard and harmful.

Knowing reputable brands is essential for choosing high-quality spacers. Recognized manufacturers usually offer products that meet international standards, with reliable construction and performance.

A leading producer of plastic spacers for floors, ceilings, and walls. Widely used in large-scale civil projects.

Besides concrete additives, it produces high-strength spacers for industrial and urban projects.

Specialized in high-load spacers for bridges, dams, and marine structures.

An affordable brand with good quality, ideal for small to mid-sized construction. Known for variety and availability.

Produces advanced spacers compatible with harsh chemical and wet environments. Used in power plants and tunnels.

A top European brand for formwork and precision spacers, popular in oil, gas, and industrial projects.

Australian brand known for innovative designs suited to tropical climates and thermal stress zones.

4.Don Construction Products (DCP) – UK

Offers durable spacers for underground structures like subways and treatment plants. Well-distributed across the Middle East.

Guaranteed Material Quality: Top brands use high-grade raw materials.

Dimensional and Mechanical Stability: High-quality spacers won’t deform under load.

Independent Lab Testing: Major brands test products in certified laboratories.

Technical Support: Reputable brands offer pre-purchase advice, installation guidance, and warranties.

Using low-quality or counterfeit spacers

Incorrect arrangement causing rebar displacement

Inadequate installation in critical areas (corners, edges)

Choosing unapproved spacers to cut costs

International codes like ACI, DIN, and Iran’s National Building Regulations (Part 9) specify the minimum rebar cover in concrete. Spacers are practical tools to implement these requirements. Following these standards improves structural safety and enhances the project's inspection outcomes.

Though often overlooked, using spacers in concrete pouring has a profound impact on the quality, safety, and durability of structures. These small components play a major role in preventing rebar corrosion, strengthening the structure, and ensuring compliance with engineering standards.

Ahan Pouya with more than a decade of best-selling experience, adheres to professional and ethical principles in the field of selling and buying at inside and outside the borders of Iran, helping you in the steel industry.