One of the most important steps in the path of quality control and welded efficiency is measurement and welding fittings. External inspections allow you to find external welding defects such as micronutrients, defects created at the structure level and cracks, inappropriate and inadequate welding, defects, etc.

One of these important inspections is eye inspection, which is an important tool that itself has different types that can be controlled and investigated.

With the help of welding gauges, we can control the welded parts and fittings in terms of different dimensions, on the other hand, we can control the frozen slope surfaces in terms of the slope angle it has.

We can also use welding gauges to assemble the necessary distances between parts. With these tools, it is possible to check whether the parts are leveled before assembly and welding and finally with their help, the possible shortcomings on the weld surface can be controlled in terms of length, width and depth.

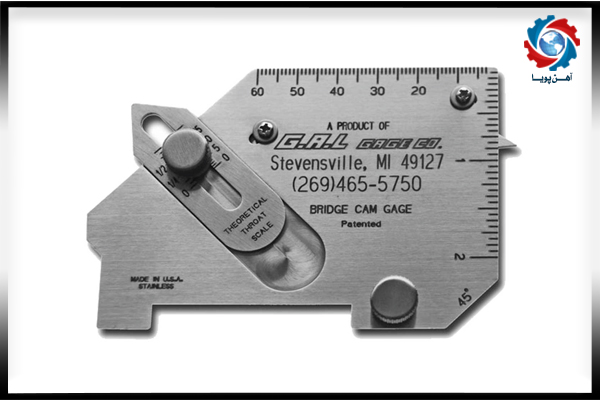

This type of welding gauge, like the Cambridge gauge, is one of the most widely used gauges in weld inspection. This puzzler has many uses in inspection science.

The applications of this type of weld include the ability to measure weld pollen, the height of the corner weld, the shin of the corner weld or the size of the weld.

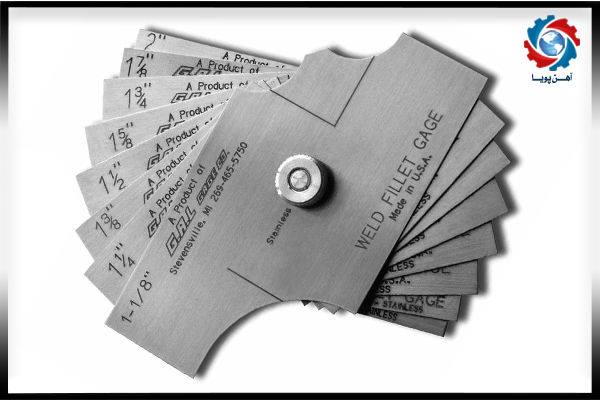

This type of weld includes a set of gauges of the same sizes, which is used to measure the length and height of the corner weld. These types of gauges are mostly used to measure weld pollen with a size of 1 to 1.8 inches.

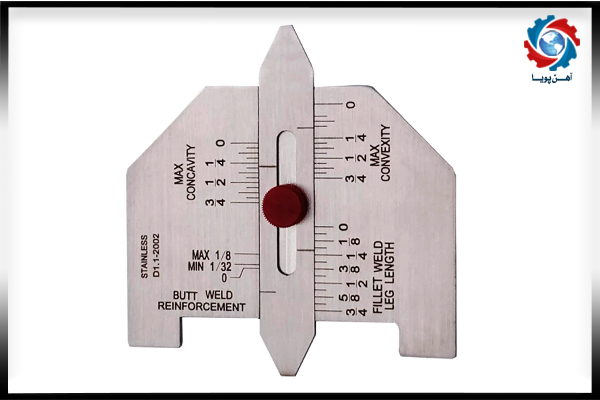

The way this type of gauge operates is multifaceted like the Cambridge gauge, and with this type of gauge, we can measure different amounts such as the height of the weld pollen or the length of the cornered pimples.

This type of gauge is a stainless steel tool that is used for alignment measurements and internal adaptations. The application area of this measure is in evaluating the assembly and conformity of pipes and fittings with high sensitivity for alignment of connection components.

1.Ability to measure corner welding

2.Capable of measuring crown height

3.Ability to measure the root distance of the assembled connection

.jpg)

Ahan Pouya with more than a decade of best-selling experience, adheres to professional and ethical principles in the field of selling and buying at inside and outside the borders of Iran, helping you in the steel industry.