Iron and steel are the most widely used metals in the world Which are considered by manufacturers and craftsmen due to their different efficiencies and strength But the special problem of this metal is that it rusts if it is not covered properly. This bell leaves a red , brown or orange layer on the metal , destroying its efficiency . Therefore, it is very important to remove iron and steel tools and equipment from rust, and this is done depending on the type of rust piece. There are numerous industrial and domestic methods to remove iron rust . The choice of each depends on the size of the piece and the degree of rust.

Iron is an element known by the name of Fe in Mendeleev . It reacts easily with moisture and oxygen, resulting in the production of iron rust or iron oxide. Iron rusting is an oxidation reaction because iron ions are separated and added to oxygen. Of course, it should be noted that oxygen alone can not oxidize iron, and moisture is also needed. Factors such as humidity , salt water , carbon dioxide and many acidic substances can rust iron and lead to iron rust . To prevent this from happening, iron or steel tools must be well corroded by various coatings Thus , iron is made with various alloying elements Or they use galvanized and protective coatings to insulate it.

Iron rust is divided into two types: destructive corrosion and stable corrosion.

Its stable type is actually a type of rust that creates a layer on the metal and prevents corrosion of its lower parts. But its destructive type must be eliminated quickly because it causes the metal device to fail and corrode and break. The chemical composition of iron also changes during chemical reactions that lead to rust And that will result in the collapse of the metal surface . If the rust is not cleaned from the metal surface in time, it will gradually penetrate into the underlying layers and wear them out. This exhaustion causes failure of various instruments and heavy losses to replace them . This is more about industrial machinery , which is expensive in terms of price and it is difficult to replace them .

Many practical and applied methods are used to remove iron rust that We will examine some of them.

This method is one of the sub-spraying methods that is used to clean surfaces from rust and dirt. Sub-spraying is a type of surface cleaning operation performed by natural abrasives with high air pressure. Sandblasting is the process of throwing sand through high air pressure to the desired surface. Compressed air is considered as the source of power in this process And it throws the abrasive, that is, the same sand, with great pressure on the rusty surface. This is a traditional method that has been used for a long time . Dust, oil and grease are used not only to clean rusted surfaces but also to clean surfaces. They also use this cleaning method to prepare surfaces for staining . Sandblast is the most common method of removing iron rust from different surfaces using natural materials such as silica and metal oxide in different sizes . In this method, air acceleration and abrasives are also controlled depending on the thickness of the layer. Sandblasting is a chemical-free method that allows access to more remote areas during cleaning. It is to be mentioned that this method has been the most effective way to clean surfaces for over a hundred years . Of course, the sandblasting method also has disadvantages, among which we can mention the possibility of tearing the surface during the operation. The abrasive particles that are dispersed while working in space are also harmful to health . This method is not used for all surfaces, especially soft surfaces.

Shot blasting is another method of sandblasting that has a function similar to sandblasting but differs in terms of abrasives. In this method, which is used to remove iron rust, metal balls are used instead of siliceous sand. Shot blast is more aggressive than sandblast and has a wider range of applications because it performs better for thicker layers of rust as well as wider surfaces. Shot blast can not only help remove rust, but also improve hardness, strengthen surfaces and create smooth surfaces. It is to be noted that BLAST does not apply for small parts because the high pressure of this method changes the shape of the device .

It may be hard to believe that water can also remove rust . The high pressure waterjet method is used to clean rusty surfaces . The waterjet consists of a high pressure nozzle that converts compressive energy into kinetic and mechanical energy and removes the rusty layer from the iron metal. Other components of the waterjet include high pressure pump, high pressure hose, high pressure water spray gun, filter, booster pump.

The method of working with waterjet is that first the water pressure is increased up to three times by the booster pump. The same water after passing through the filters and reaching the nozzle increases up to 2500 times and is ready to be thrown.

The advantage of this approach to other methods is that it does not produce pollution. It is worth mentioning that the rate of pressure and the flow rate for proper functioning should be properly controlled and the rate of both sides together reduces its effectiveness .

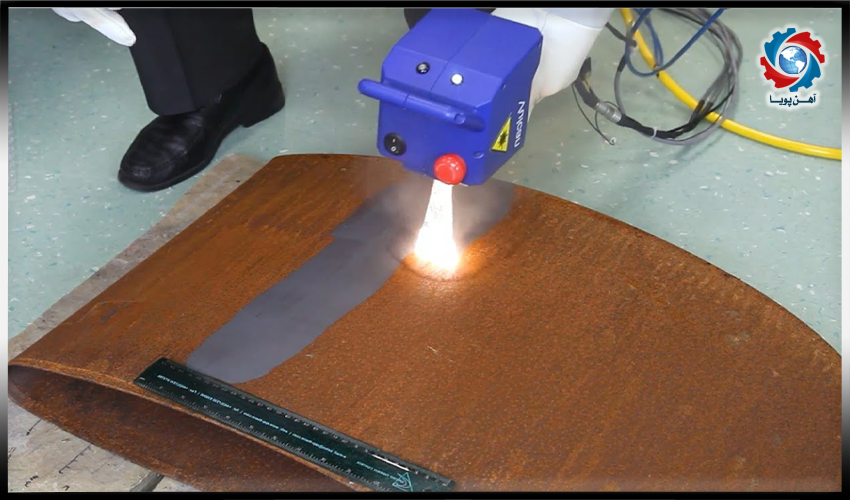

Laser is one of the newest and most up-to-date methods of removing iron rust from iron surfaces . With the lowest energy consumption , this method can clear a broader range of corroded surfaces . The laser technique can also remove the tool used at high temperatures , such as jet engines , combustion chambers , etc.

Laser cleaning works in such a way that high-power beams radiate to the rust site, eliminating any corrosion and corrosion-induced corrosion. This method is particularly well received because of its effectiveness , speed and speed , as well as large usage .

Lasers can be used to clean all surfaces , even soft surfaces and small parts . The laser also does not damage the intended piece And its volume and speed can be controlled depending on how much work is done . The laser method is used not only to remove rust from iron, but also to clean surfaces of aluminum, copper, brass, semi-hard steel, anodized aluminum, thick plastic, alloy steel.

Acid washing is also one of the most popular methods to remove iron rust. Acid is used to wash iron rust and clean iron surfaces . One of the acids used in acid etching method is Oxalic acid , which is required for every gallon of water in a three - to - three tablespoon . Oxalic acid works in such a way that as soon as the rusted metal is placed in it, it enters into a chemical reaction with iron rust to form a colorless, water-soluble ionic complex. In fact, oxalic acid converts all iron rust into ionic solutions, which can then be easily washed and cleaned with water.

The duration of the immersion of iron in oxalic acid varies from several hours to a few days , depending on the amount of rust and the size of the piece . After rust is removed , stainless steel has to be cleaned well with water .

Ahan Pouya with more than a decade of best-selling experience, adheres to professional and ethical principles in the field of selling and buying at inside and outside the borders of Iran, helping you in the steel industry.