Painting galvanized sheet is a bit difficult This is difficult because the surface of the sheet is smooth and polished and it is a little difficult to place the paint on a smooth surface Also, drying the paint on it requires special skills and operations.

1.The surface of the sheet should be clean and free of any grease It has to be checked that there is no hole in the card or a hole . First, the surface is washed with detergent, such as Vitex, to remove grease.

2.After that , they dry the cards thoroughly and wipe them out with cloth . There is a white rust on the sheets that looks like dandruff (white dandruff of galvanized sheet) which must be removed by sanding. Sanding is done in a circular motion (circular) It helps to smooth all surfaces of one hand and smooth . After sanding, a cloth soaked in warm water should be applied to the sheet to remove all the sanded paint.

3.In the next step , you should wash the cards with an acidic substance that contains a small percentage of the acid properties . Basically, they use white vinegar. The white vinegar is rubbed on the galvanized sheet with a cloth so that the color settles well on the sheet and does not slip. This causes the sheet to become rough. After one or two hours of vinegaring, the sheet begins to corrode and the excess paint is removed. This is to get the color better on the sheet. This step takes time for the sheet to dry completely.

4.Then the latex base primer is applied with a brush or spray If we want cards to be resistant to scratch and be used in industrial or open environments , a layer of epoxy primers must be used .

5.After applying the primer, leave it for about two to six hours until the primers are completely dry . It should not be wet because the primer should stop the color sticking to the surface if the primer is wet .

6.After that, special galvanized paints are applied as the first layer on the surface to dry . This paint is done with a brush, brush or spray. After four hours , the second layer of special colours is turning over the leaves to get ready . For galvanized sheets, two layers of paint are used. Of course, if special galvanized paints are used, twice is enough.

7.When the painting operation is complete and the sheet is dry, the quality control supervisors check the painting method and the paint coating. This monitoring includes such things as paint thickness, paint compliance with special standards, paint adhesion, paint quality on surfaces. Observers first inspect the sheets with the naked eye and then test the thickness of the painted layer according to DIN EN ISO 2360 and match the color according to ISO7724.

This color is different from ordinary colors and the type of structure and its formulation is different For example, the difference between galvanized paint and ordinary paint can be categorized as follows :

1.The drying time of galvanized paint is less than normal paint and it dries faster.

2.The type of this paint is such that it has a very high adhesion and sticks to the sheet in a special way.

3.Due to its high adhesion, this paint does not flake or wrinkle and does not crumble into a powder after drying.

4.The high resistance of this color is very different from the usual temperature and temperature In such a way that these colors do not change color against heat and do not melt.

5.Special paints can be repaired That is, if these sheets are scratched and a line remains on the surface, we clean the scratch with a clean cloth and repair the damaged part with a repair solution that contains RAL.

6.It is anti-UV rays of the sun.

7.is resistant to hard weather conditions.

8.Washable.

9.It acts as insulation on the sheet and prevents wasting of cooling and heating energy.

10.It 's easy to implement and can be dyed with brush and spray.

11.Can be repainted.

12.Can be run in all weather conditions.

13.It has resistance to impact and hammer.

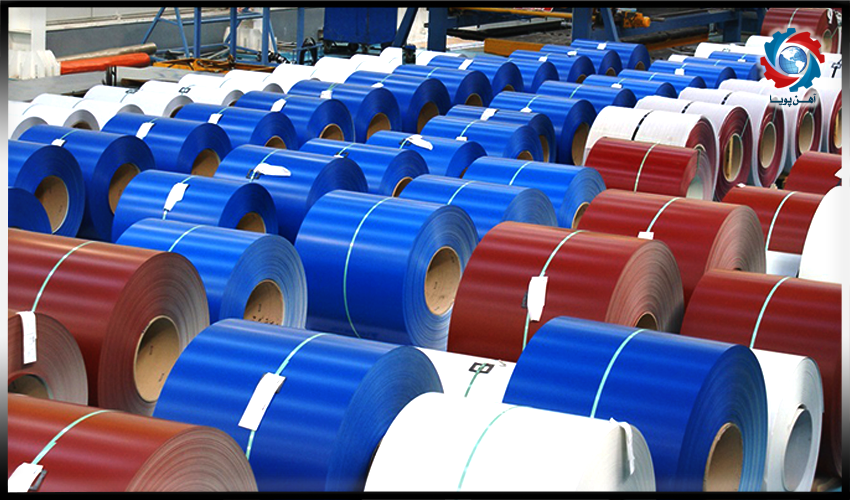

For example, this paint protects welded and perforated points and prevents further damage Can be used to repair, stain and recharge galvanized structures. Protects cathodic metal structures And it doesn 't need the expertise of the expert . Color variation for galvanized sheets is more than 16 colors that are produced with a thickness of about 35 microns.

galvacot is a type of galvanized plate that does not require a primer in the following steps . It has the highest adhesion to the surface from other colors . Galvacots have a high hardness, and this is due to their very strong mechanical properties, which makes it not limited in shade. This type of product is non-flammable and is thermoplastic.

Because the paint gives more coverage and resistance to galvanized sheets and increases its useful life, this product is used in the roofs of buildings, technical and control rooms, insulation of containers and containers, the body of home appliances, Cabinets, metal window frames, air ducts and. Are used.

These sprays are in the form of zinc powder mixed with paint and weigh about 400 mg and they 're resistant to 600 degrees Celsius. The color spectrum of this spray includes two colors, silver and gray. It has high adhesive strength and can be applied on epoxy and polyurethane . The positive feature of this spray is a very small amount of time drying . The spray drying quickly from the paint brush and requires less than an hour to dry . Brands that have spray paint for galvanized sheet in Iran include Duplicate, Vicon, Embrosol, Zetex and… .

Ahan Pouya with more than a decade of best-selling experience, adheres to professional and ethical principles in the field of selling and buying at inside and outside the borders of Iran, helping you in the steel industry.