Air dry steel (HSS), which stands for English equivalent high-speed steels, is classified as a tool steel and is commonly used in the form of shear tool steel. Air dry steels or pulvers are commonly used in saw blades and drills.

This steel is superior to the old instrument steel used in the past, because fast-moving steels or HSS can survive at higher temperatures without losing their hardness or form. This feature allows fast steels, which, like their name, "fast steel", have faster cutting than high-carbon steels.

At room temperature, in generally recommended heat treatment, air dry steels usually show good hardness and abrasion resistance compared to conventional instrument steels or carbon steels.

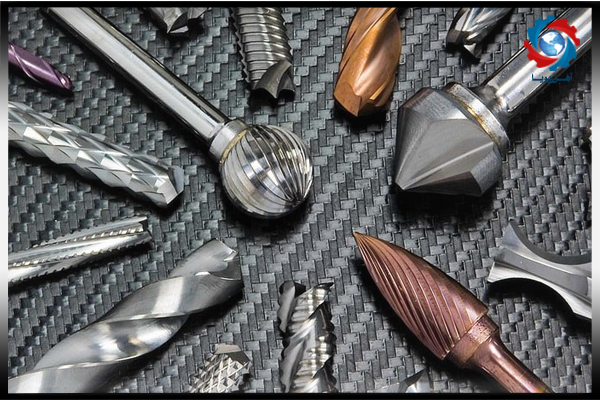

1.The main application of air dry steels is the manufacture of a variety of shear tools, including drills, milling cutters (pavement tools), drillers, gear sharpening tools, saw blades, lathe blades, etc. Also, the use of these steels for stamping and molding is also increasing .

2.Fast steels also found a market among steel hand tools, where their relatively good density in high hardness, combined with high abrasion resistance, has made them suitable for low-speed applications for sharp edges. Like: drill drills, Damascus kitchen knives and pocket knives .

3.Steel is the most popular steel tool for use in superstition because the speed of movement at the edges is very high for hand tools steel and of course HSS steels hold the edges for longer compared to carbon instrument steel.

This grade of fast steels, because they have more tungsten and vanadium, have more hardness and drift than other standards in the fast steel group.

Elasticity coefficient (31 x 106 psi) : 217

Special gravity: 26

Density: 23

Thermal Conductivity (W/m.K): 0

Machining: 10-15%

Hardening at 1200-1230 °C is done by oil, cooling in the air or hot bath at 540°C. Its hardness after cooling is 64-66HRC.

Heat 800 –860 °C and then gently cool it in the furnace. this will create the most hardness .

As mentioned above, 1.3207 air dry steel has many applications due to its high hardness and abrasion resistance during cutting, including :

Special shear tools

Khankshi Tools

Milling & Milling Tools

Making lathes

Tool for working for the user on wood

Drill Construction

Saw blade

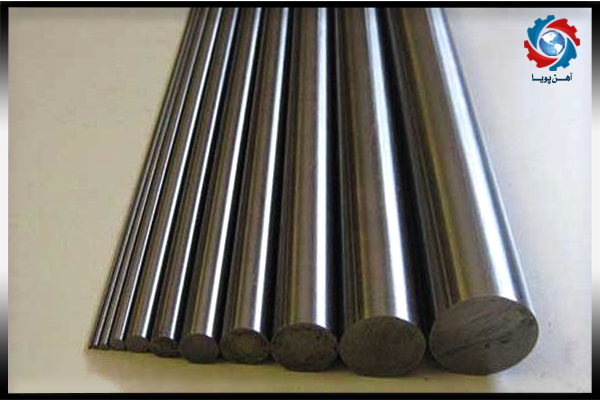

Tungsten 1.3355 pulp steel is one of the main tungsten tool steels, tungsten has a great application in the production of instrument steels and is recently used in the production of heat-resistant alloy steels. Therefore, this steel is also used in the production of fast-moving steel. Although all tungsten steel grades are used in limited quantities due to the cost and difficulty of tungsten availability. Of group T steels, 1.3355 or T1 air dry steels are the most widely used.

1.3355 Fast steel is hardened with oil and air, which has a good comprehensive performance. HSS 1.3350 steel has a lot of hardness equivalent to 62 to 66 HRC and also has rigidity, strength and thermal resistance, which makes it an excellent fast steel material.

Density: g/cm3 8.67

Hardening temperature: 1240-1280

Annealing temperature :: 770-840

Tempering temperature: 540-570

Cooling environment (Quench): oil – air – salt bath

Elastic coefficient: 190-210 GPa

Forging temperature: 930-1150

Ahan Pouya with more than a decade of best-selling experience, adheres to professional and ethical principles in the field of selling and buying at inside and outside the borders of Iran, helping you in the steel industry.